How To Choose A Power Tool Battery?

As an energy storage device integrating high energy density and high voltage, lithium-ion batteries have been widely used in mobile and wireless electronic equipment, power tools, hybrid and electric vehicles and other fields.

What types of power tool batteries are there?

1. Ordinary lithium-ion battery for power tool battery

If the power tool battery is made of ordinary lithium-ion battery, it must meet the high-rate discharge performance to meet the working requirements of the power tool. However, ordinary lithium-ion batteries cannot achieve higher rate discharge performance due to cost and material limitations. Therefore, everyone buys relatively cheap lithium power tool batteries in the market.

When using it, I often feel like this. It’s okay to use it just after it’s fully charged. But after a while, it became obvious that the power of the power tool dropped significantly, feeling limp and lacking in energy. At the same time, ordinary lithium-ion batteries have average high-temperature resistance, so their service life is relatively short.

2. Ni-MH battery for power tool battery

Nickel-metal hydride batteries for power tools are not as energy-dense as lithium-ion batteries. Therefore, in the same battery pack space, the capacity of nickel-metal hydride batteries is smaller than that of lithium-ion batteries. However, the consistency of nickel-metal hydride battery cells is higher than that of lithium-ion batteries. Therefore, the safety performance of nickel-metal hydride battery packs is better than that of lithium-ion batteries. At the same time, nickel-metal hydride batteries can achieve a discharge capacity of 15C rate or higher, which can fully meet the requirements of the working characteristics of power tools.

Of course, nickel-metal hydride batteries are heavier than lithium-ion batteries, but they are cheaper than lithium-ion batteries in terms of production and manufacturing costs and market price, and are still relatively competitive.

Also, the low-temperature performance of nickel-metal hydride batteries is much worse than that of low-temperature lithium iron phosphate batteries and low-temperature polymer lithium-ion batteries. Therefore, nickel-metal hydride batteries are not suitable for power tool batteries used in low-temperature areas.

3. Lithium iron phosphate battery for power tool battery

Lithium iron phosphate batteries for power tool batteries have certain advantages, and their high-temperature resistance is better than other types of lithium-ion batteries. At the same time, it can achieve discharge performance above the 30C rate. It has ideal results when used in normal and wide-temperature environments.

Compared with nickel-metal hydride batteries, its low-temperature performance and energy density are relatively much better, and its service life is also longer than that of nickel-metal hydride batteries.

Nickel metal hydride batteries have a memory effect, but lithium iron phosphate batteries do not. The current technology of lithium iron phosphate batteries is insufficient compared to nickel-metal hydride batteries, so the battery consistency is relatively poor. Battery packs are slightly less safe than nickel-metal hydride batteries.

4. Polymer lithium-ion battery for power tool battery

Among power tool batteries, polymer lithium-ion batteries should be the most expensive. Polymer lithium-ion batteries are not only higher in energy density but also the best in achieving ultra-high rate discharge performance.

The reason why polymer lithium-ion batteries are expensive is that they use rare materials with high energy density, and their production and manufacturing technology requirements are relatively high.

Its disadvantage is that its internal high-temperature performance is slightly worse than that of iron phosphate batteries, and is similar to that of nickel-metal hydride batteries.

At present, the vast majority of power tools still use 18650 lithium batteries as the main power source. However, with the advent of 21700 lithium batteries, this situation is gradually being broken.

Should I choose 18650 or 21700 lithium batteries for power tools?

21700, 18650, 20700, etc. only refer to the physical size of lithium-ion batteries. For example, for an 18650 lithium battery, 18 represents the circumference, 65 represents the length, and 0 represents the cylindrical battery. 18650 batteries are not only lithium batteries, nickel metal hydride batteries also have the size of 18650.

Compared with the 18650 battery, the extra 5 mm length and 3 mm diameter of the 21700 battery cell can increase its volume by 47%. This means an additional 7,700 cubic millimeters of space can be used to fill the anode, cathode and electrolyte materials that deliver energy. It also means that the 21700 lithium battery can have a higher capacity than the 18650 lithium battery.

Higher capacity equals longer battery life

The most obvious benefit compared to the 21700 and 18650, the extra space allows more energy to run your tools longer. We have seen batteries powered by 18650 cells with capacities ranging from 1.5Ah (1500mAh) to 3.0Ah (3000mAh) per cell.

However, the high-end 18650 battery cell (3.0Ah) has already experienced batch problems, which is why most manufacturers put the 2.5Ah (2500 mAh) battery cell first.

On the other hand, for power tool batteries, the 21700 cell starts at 3.0Ah (3000mAh) and can reach up to 4.0Ah (4000mAh). This is why we can see compact (1P) battery packs labeled 3Ah or 4Ah, all the way up to larger cells of 12Ah (3P).

Are ternary lithium batteries used in power tools safe?

The following is a comparison of the capacities of various specifications of conventional power tool batteries.

18650

- Compact 1P battery: 2.0Ah–3.0Ah (36 Wh–54 Wh)

- Universal 2P battery: 4.0Ah–6.0Ah (72 Wh to 108 Wh)

- Large capacity 3P battery: 9.0Ah (162Wh)

21700

- Compact 1P battery: 3.0Ah–4.0Ah (54Wh–72Wh)

- Universal 2P battery: 6.0Ah–8.0Ah (108 Wh–144 Wh)

- Large capacity 3P battery: 9Ah–12Ah (162 Wh–216 Wh)

*Note: The above is regardless of the nominal voltage of the battery.

How to choose between an 18650 lithium battery and a 21700 lithium battery

The 18650 lithium battery has been one of the lithium batteries used in power tools for a long time. In addition to being the right size, the weight is also better for carrying. 21700 has a larger size space than 18650 and is also heavier and larger than 18650. However, it is obvious that 21700 can provide stronger power and longer service life at the same time.

Both batteries can be used with power tools. If you have to make a choice between two batteries, you should focus more on practical applications.

When choosing batteries, be sure to choose regular manufacturers to ensure quality and after-sales service. Ufine has been focusing on lithium battery production for 15 years. Our products are safe and stable, have strong battery life, are small in size, environmentally friendly, have a long lifespan and are durable. The products have passed multiple certifications from the country and around the world, making it a battery brand manufacturer worth choosing.

High Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Power Tool Battery

-

What is the range of capacity and voltage for custom batteries?

-

What is the lead time for lithium battery production and delivery?

-

Can I get samples of lithium batteries before placing a bulk order?

-

What certifications should lithium batteries have?

Latest Blogs

About Lithium Battery Industry News

Paper Battery vs. Flexible Battery: What’s the Difference and Which Is Better?

Paper vs. flexible batteries: learn the key differences, benefits, and which power source fits best for wearables, sensors, and smart tech.

2025/04/11 Ufine

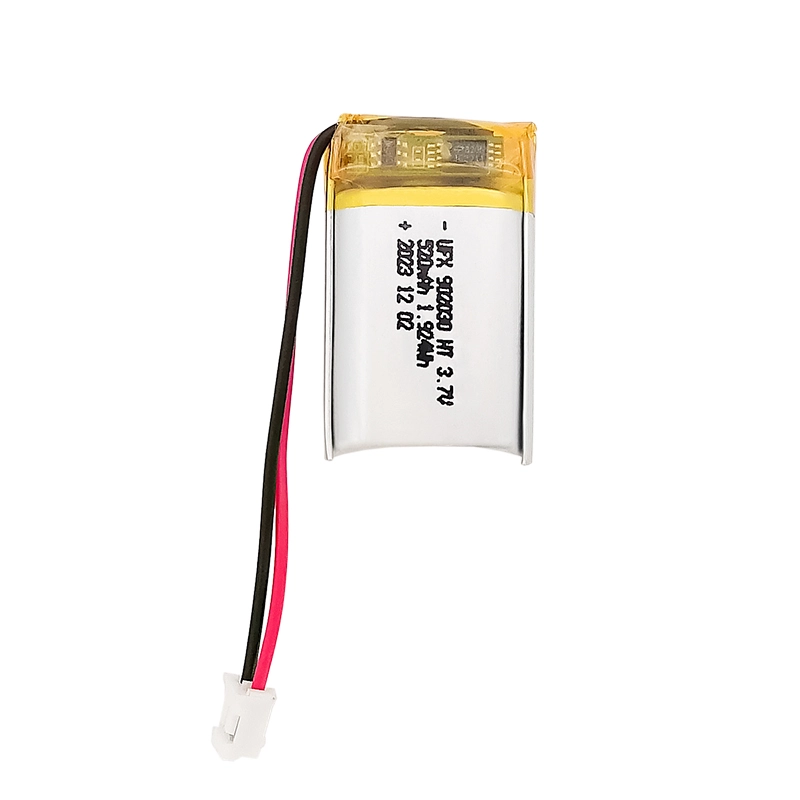

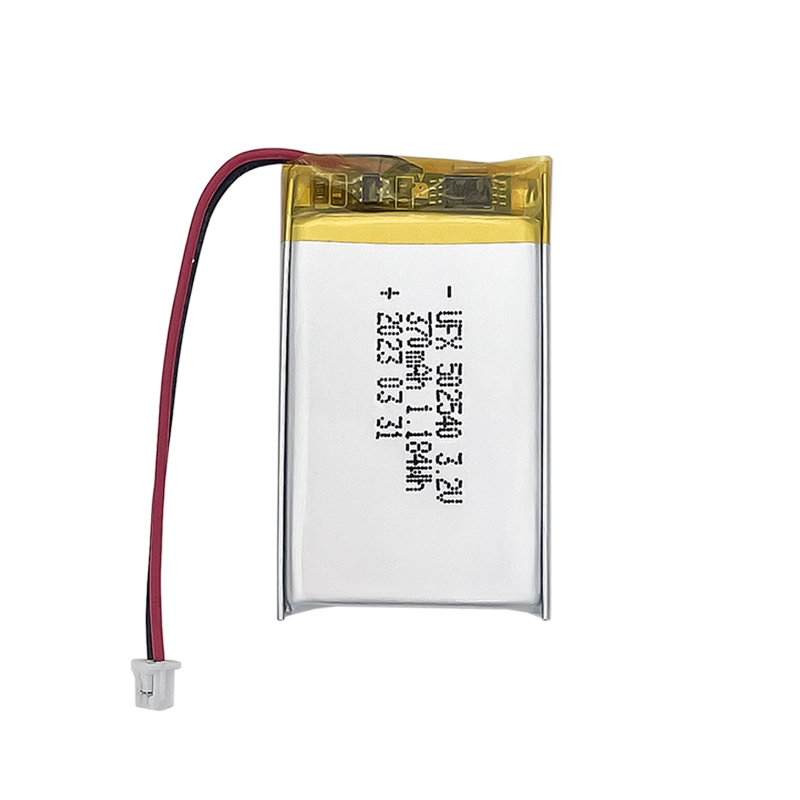

What to Know Before Buying a Tiny LiPo Battery for Your Project

Tiny LiPo batteries are powerful and compact. Learn how to choose the right one for your project with specs, safety, and charging tips.

2025/04/11 Ufine

Bloated LiPo Battery: Will It Explode?

Will a bloated LiPo battery explode? Discover the causes, risks, safety steps, and expert tips to avoid disaster and protect your gear. Must-read safety guide!

2025/04/10 Ufine

12V 100Ah Lithium Ion Battery Price: Full Guide

Learn about 12V 100Ah lithium-ion battery price, from cost ranges to best brands, hidden fees, and how to get the best deal. A must-read for smart buyers!

2025/04/10 Ufine

Resistance and Conductivity: What It Means for Your Lithium Batteries

Resistance and conductivity impact lithium battery performance, lifespan, and safety—learn how they work and why they matter.

2025/04/10 Ufine

What Is a Semi Solid State Battery and Why Should You Care?

Semi-solid-state batteries combine safety and high energy density, making them ideal for EVs, electronics, and future energy storage.

2025/04/10 Ufine