Elevate Your Wearables With Advanced Wearable Device Battery

Not only are wearable devices very constrained in size, but they must also be very light as comfort is important as they are worn for long periods of time. Therefore, the wearable device battery must be as small as possible. Not only that, repeated research conducted by IDC and GMI shows that battery life is the number one consideration for consumers when purchasing battery-powered convenience products. Therefore, a high-capacity wearable device battery is very important to the success of the product.

Meeting these two requirements simultaneously makes the battery challenge even more daunting. Fortunately, lithium batteries have many properties that enable them to overcome this challenge, making them ideal for wearable device applications.

First, they offer high energy density, allowing system design engineers to choose smaller and lighter batteries that can provide longer operating times. Meanwhile, lithium batteries typically operate at 3.7 V, compared to 1.2V for nickel-metal hydride or nickel-cadmium batteries. This means that lithium batteries require fewer cells, which also contributes to smaller and lighter systems.

In addition, the self-discharge rate of wearable device lithium batteries is also much lower than that of nickel-based batteries, which is about 2% per month. And nickel metal hydride and nickel-cadmium batteries are up to 5% per day. Not only does this reduce the number of recharges, but the battery can be used again at any time after being left for a long time, making the system more customer-friendly.

Of course, all technologies have their shortcomings. For example, lithium-ion batteries are more complex to manufacture than nickel-based rechargeable batteries, so they are more expensive. But as a mass-produced product, economies of scale and continued technological improvements are rapidly reducing its manufacturing costs.

In terms of safety, most lithium-ion batteries have internal protection circuits that protect against overvoltage or undervoltage to a certain extent. However, the charging process for lithium-ion batteries is still much more complicated than for nickel-based rechargeable batteries.

Lithium-ion batteries: enabling comfortable and convenient wearable devices

●Small battery, long battery life, high energy density

●Higher operating voltage means fewer cells and smaller systems

●Slower self-discharge: fewer charging times, ready for use at any time

Charging jump of wearable device battery

To avoid these safety issues, lithium-ion batteries require constant current (CC) and constant voltage (CV) charging processes. In this process, the wearable device battery is first charged with a fixed current until it reaches the set voltage. The charging circuit then switches to constant voltage mode, providing the necessary current to maintain the set voltage.

For optimal charging, careful trade-offs must be made in the selection of current and voltage levels. Charging at a higher voltage can increase battery capacity, but voltages that are too high can cause the battery to become stressed or overcharged, causing permanent damage, instability and danger.

Likewise, higher charging current allows for faster charging, but at the cost of reduced battery capacity. A 30% reduction in charging current can increase the amount of charge stored in the battery by as much as 10%.

Therefore, the charging current is usually set to half the battery capacity (the maximum current that the battery can sustain for one hour), and the voltage is set to 4.2 V per cell.

However, it turns out that using a slightly smaller charging current and voltage can slow down the aging of the battery, allowing it to survive more charging cycles with a higher capacity.

Wearable device battery safety

Because of this complexity, charging solutions must be able to closely monitor charging current and voltage. And provide a stable control loop to keep the charging current and voltage at appropriate values at the appropriate point in the charging cycle (that is, the current remains constant in the first stage and the voltage remains constant in the second stage).

Charging solutions also need to be fully tested according to strict standards. These standards contain more extensive testing conditions than those required for nickel-based rechargeable batteries, while also including tests related to the batteries themselves.

wearable device battery charging cycle

The wearable device battery charging process starts as soon as the input voltage is detected. If the battery power is severely depleted (for example, the voltage is lower than 3V), the charging algorithm will trigger a precharge phase to “precharge” the battery with a low current (about 10% of the battery capacity) until the battery can accept full charging current. This prevents overheating.

After the voltage reaches the appropriate level, the charging algorithm switches to the current stage, charging the battery with a higher current (up to the battery’s capacity) until the voltage reaches 4.2 V (standard value). At this time, the charger enters the constant voltage stage to avoid the danger of overcharging. During this stage, the voltage remains at 4.2 V, while the current decreases to around 10% of the battery capacity. The transition from the constant current phase to the constant voltage phase is done gradually and smoothly to avoid battery damage.

By this time the battery is fully charged. If the battery is still connected after being fully charged, the charger enters the voltage monitoring stage to provide periodic recharging to make up for the power consumption due to battery self-discharge. Recharge is usually performed when the battery’s open circuit voltage drops below 4.0 V.

Safe, convenient and reliable wearables

The wearable device market is growing rapidly now and will continue to do so in the coming years. Progress has been made in both system power consumption and energy harvesting potential. But we are still a long way from the goal of wearable devices harvesting energy from their environment to charge. Therefore, wearable devices and other feature-rich IoT applications still require the use of rechargeable batteries.

Lithium-ion batteries are small, lightweight and high-capacity, helping system design engineers meet size constraints while providing long battery life that satisfies consumers. Its higher operating voltage means fewer cells are needed, further reducing system size and increasing design flexibility.

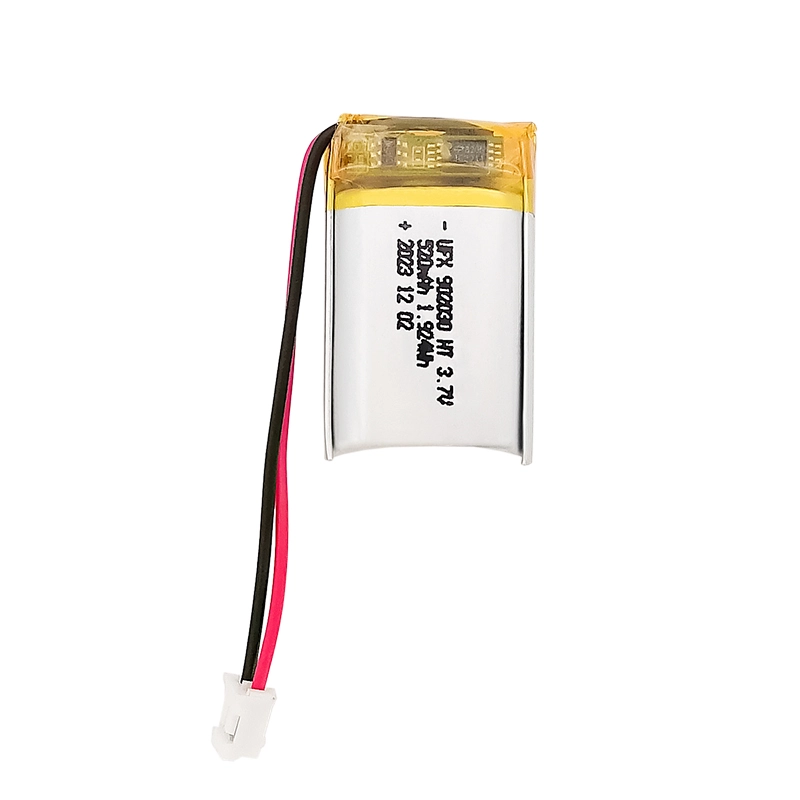

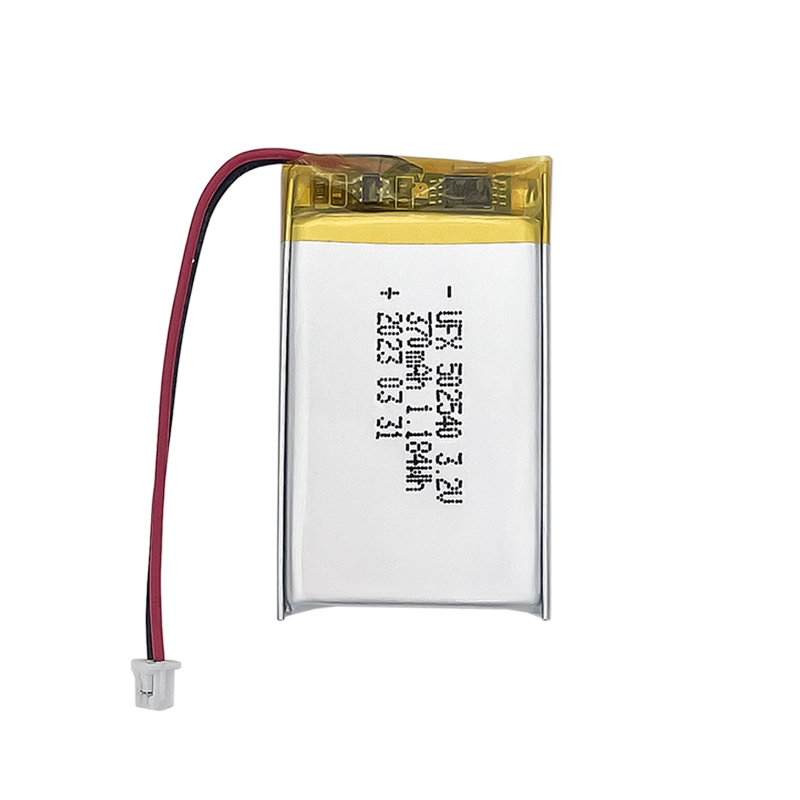

Ufine wearable device battery

Guangdong Ufine New Energy Co., Ltd. is a high-tech enterprise specializing in the research, development, design and production of polymer lithium-ion batteries. Ufine’s wearable device battery provides built-in protection against overvoltage charging, Undervoltage discharge, and overcurrent charge (discharge).

Ufine has been focusing on battery manufacturing technology for 15 years. It is safe and stable, has no risk of explosion, has strong battery life, long-lasting power, high charging conversion rate, does not get hot, has long service life, is durable, has production qualifications and its products have passed many national and global certifications. Certification.

High Energy Density

It stores large amounts of energy in a smaller and lighter package

Longer Cycle Life

Withstands extensive charge and discharge cycles

Low Self-Discharge

Maintains power longer when not in use

Safety

Minimizes the risk of accidents and ensures safe operation

More Information About Wearable Device Battery

-

What is the minimum order quantity (MOQ) for lithium batteries?

-

What is the lead time for lithium battery production and delivery?

-

Can your lithium batteries meet specific country or region certification requirements?

-

How long does it take to make a sample of a custom battery?

Latest Blogs

About Lithium Battery Industry News

Paper Battery vs. Flexible Battery: What’s the Difference and Which Is Better?

Paper vs. flexible batteries: learn the key differences, benefits, and which power source fits best for wearables, sensors, and smart tech.

2025/04/11 Ufine

What to Know Before Buying a Tiny LiPo Battery for Your Project

Tiny LiPo batteries are powerful and compact. Learn how to choose the right one for your project with specs, safety, and charging tips.

2025/04/11 Ufine

Bloated LiPo Battery: Will It Explode?

Will a bloated LiPo battery explode? Discover the causes, risks, safety steps, and expert tips to avoid disaster and protect your gear. Must-read safety guide!

2025/04/10 Ufine

12V 100Ah Lithium Ion Battery Price: Full Guide

Learn about 12V 100Ah lithium-ion battery price, from cost ranges to best brands, hidden fees, and how to get the best deal. A must-read for smart buyers!

2025/04/10 Ufine

Resistance and Conductivity: What It Means for Your Lithium Batteries

Resistance and conductivity impact lithium battery performance, lifespan, and safety—learn how they work and why they matter.

2025/04/10 Ufine

What Is a Semi Solid State Battery and Why Should You Care?

Semi-solid-state batteries combine safety and high energy density, making them ideal for EVs, electronics, and future energy storage.

2025/04/10 Ufine