- Part 1. How does the electric vehicle battery power the EV?

- Part 2. Electric vehicle battery types

- Part 3. Which electric vehicle battery is the best?

- Part 4. Common EV battery structure and composition

- Part 5. What is the cost of an EV battery?

- Part 6. Why are EV batteries so expensive?

- Part 7. Which electric vehicle battery is the cheapest?

- Part 8. Which battery should I buy?

- Part 9. Conclusion

Electric vehicles (EVs) are rapidly gaining popularity, but one of the primary concerns for potential buyers is the cost of the battery. This article delves into the complexities of EV battery costs, exploring factors that influence pricing, different battery types, and the potential for future cost reductions.

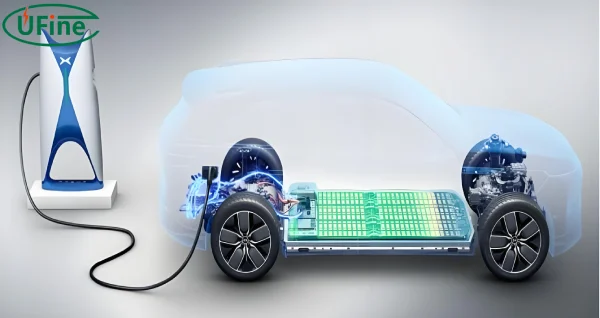

Part 1. How does the electric vehicle battery power the EV?

An electric vehicle’s propulsion relies on a sophisticated interplay between the battery pack and the electric motor. The battery pack, a complex assembly of individual battery cells, stores electrical energy. When the driver accelerates, the battery discharges power to drive the electric motor. Conversely, regenerative braking captures kinetic energy during deceleration, converting it into electricity and storing it back in the battery, enhancing efficiency.

Part 2. Electric vehicle battery types

The type of battery significantly impacts an EV’s performance, range, and, crucially, cost.

-

Lithium-ion (Li-ion) batteries: Dominating the EV market, Li-ion batteries offer a compelling combination of energy density, power output, and lifespan. However, variations in cathode materials result in different performance characteristics and costs.

-

Lithium cobalt oxide (LCO): High energy density but lower thermal stability.

-

Lithium manganese oxide (LMO): Improved safety but lower energy density.

-

Lithium nickel manganese cobalt oxide (NMC): Balances energy density and safety.

-

Lithium iron phosphate (LFP): Excellent safety, long cycle life, but lower energy density.

-

-

Nickel-metal hydride (NiMH) batteries: Once prevalent, NiMH batteries have largely been superseded by Li-ion due to lower energy density and shorter cycle life.

-

Lead-acid batteries: Primarily used for starting internal combustion engines, lead-acid batteries have limited applications in EVs due to their low energy density and weight.

Part 3. Which electric vehicle battery is the best?

The “best” EV battery depends on specific requirements and priorities.

-

Range: Li-ion batteries with high energy density, such as those using NMC or LCO chemistries, generally offer longer ranges.

-

Cost: LFP batteries often provide a lower upfront cost due to their abundant and less expensive materials.

-

Safety: LFP batteries are renowned for their excellent thermal stability and safety.

-

Charging speed: Different chemistries and battery management systems affect charging rates.

While Li-ion batteries currently dominate the market, advancements in solid-state and other battery technologies hold promise for future improvements in energy density, safety, and cost.

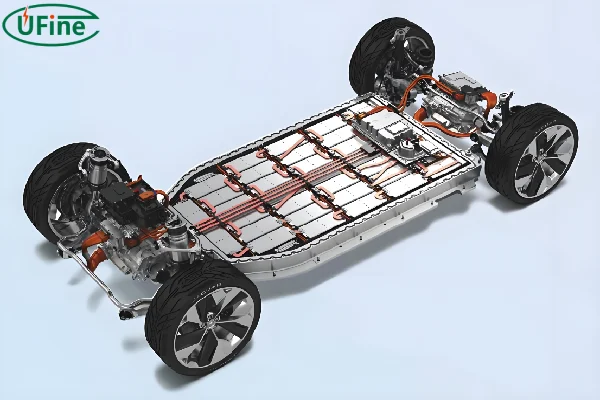

Part 4. Common EV battery structure and composition

An EV battery pack is a complex assembly comprising several key components:

-

Battery cells: The fundamental units storing energy.

-

Battery modules: Groups of cells connected in series and parallel to form modules.

-

Battery pack: Multiple modules combined with a battery management system (BMS).

-

Battery management system (BMS): Monitors and controls battery performance, ensuring optimal operation and safety.

The composition of battery cells varies based on the chosen chemistry. For instance, a typical Li-ion cell consists of a graphite anode, a cathode made of a lithium-based compound (e.g., LCO, LMO, NMC, or LFP), a separator, and an electrolyte.

Part 5. What is the cost of an EV battery?

The cost of an EV battery is a critical factor influencing the overall price of an electric vehicle. Several factors contribute to the final cost:

-

Battery capacity: Larger battery packs with higher energy storage capacity naturally command a higher price.

-

Battery chemistry: Different battery chemistries have varying production costs. For instance, LFP batteries are generally less expensive than those using cobalt-based chemistries.

-

Manufacturing process: Economies of scale, technological advancements, and production efficiency impact battery costs.

-

Raw material prices: The cost of lithium, cobalt, nickel, and other essential materials fluctuates based on market conditions and supply chain dynamics.

-

Battery management system (BMS): The complexity and sophistication of the BMS influence the overall battery pack cost.

As of 2023, the average cost of a lithium-ion battery pack for a passenger EV is estimated to be between $100 and $200 per kilowatt-hour (kWh). However, it’s essential to note that this is an average, and actual costs can vary significantly. For instance, higher-performance EVs with larger battery packs will incur higher costs.

Part 6. Why are EV batteries so expensive?

The relatively high cost of EV batteries can be attributed to several factors:

-

Raw material costs: Lithium, cobalt, and nickel, key components of lithium-ion batteries, have experienced price volatility due to supply constraints, geopolitical tensions, and increasing demand from the EV industry.

-

Manufacturing complexity: Producing lithium-ion batteries is a complex process requiring specialized equipment and skilled labor.

-

Research and development (R&D) costs: Continuous investment in battery technology is necessary to improve performance, reduce costs, and develop new chemistries.

-

Supply chain challenges: Building a robust and secure supply chain for battery materials and components is complex and costly.

-

Battery pack assembly: Integrating numerous battery cells, a BMS, and other components into a battery pack is a labor-intensive process.

Part 7. Which electric vehicle battery is the cheapest?

While lithium-ion batteries dominate the EV market, their cost remains a significant factor. Other battery technologies, such as lead-acid and nickel-metal hydride, are generally less expensive but offer inferior performance and limited applications in EVs.

Among lithium-ion chemistries, LFP batteries tend to be more cost-effective due to their lower reliance on critical and expensive materials like cobalt. However, the choice of battery chemistry depends on various factors, including desired range, charging speed, and vehicle performance.

It’s important to note that battery costs are declining as production volumes increase and technological advancements reduce manufacturing expenses.

Part 8. Which battery should I buy?

Selecting the optimal battery for an electric vehicle is a complex decision influenced by various factors:

-

Driving range: For extended range, high-energy-density batteries like those using NMC or LCO chemistries are preferred.

-

Charging speed: Some battery chemistries, such as certain NMC variants, enable faster charging.

-

Climate: Extreme temperatures can impact battery performance. LFP batteries often exhibit better performance in hot climates.

-

Budget: LFP batteries generally offer a lower upfront cost compared to other lithium-ion chemistries.

-

Vehicle type: Different vehicle segments have varying battery requirements. For example, compact EVs may prioritize energy efficiency, while high-performance vehicles demand high power density.

Ultimately, the ideal battery choice involves a trade-off between factors like range, performance, cost, and charging speed. It’s essential to consider individual driving habits and preferences when making a decision.

Part 9. Conclusion

The cost of electric vehicle batteries has been a significant barrier to wider EV adoption. However, ongoing technological advancements, increased production volumes, and the growing competition in the battery market are driving down prices. As battery technology continues to evolve, we can expect to see further reductions in cost and improvements in performance, making electric vehicles increasingly accessible and attractive to consumers.

Related Tags:

More Articles

고방전 배터리는 높은 전류와 발열로 배터리수명이 줄어듭니다. 구조적 한계, 사용 패턴, 충전 습관 등 실제 수명 단축 요인을 체계적으로 분석했습니다.

Capacitor vs Battery: What is the Difference?

Capacitor vs battery explained in detail. Learn the difference between capacitor and battery in energy storage, charging speed, lifespan, and real applications.

18650 Battery vs AA: Which Is Better for Your Device?

Compare 18650 vs AA batteries in capacity, voltage, rechargeability, and applications. Learn which battery type fits high-drain or everyday devices.

What is the Difference Between Battery Cell, Battery Control Module, and Battery Pack?

Compare battery cells, modules, and packs. Learn functions, design differences, control modules, and selection tips for EV, ESS, and industrial use.

How to Prevent LiPo Battery Explosion?

Can LiPo batteries explode or catch fire? Learn key causes of LiPo battery fires and proven charging, storage, and handling tips to reduce explosion risk.