What is the key difference between aluminum air and lithium-ion batteries?

The key difference between aluminum air and lithium-ion batteries lies in rechargeability and energy density. Aluminum air batteries offer extremely high energy density. Still, they are not rechargeable, while lithium-ion batteries are fully rechargeable and dominate most consumer and industrial applications today.

As the demand for energy storage grows—driven by electric vehicles (EVs), renewable energy, and portable electronics—the search for better alternatives to lithium-ion batteries continues. One of the most talked-about contenders is the aluminum air battery. But is it better?

This article explores the costs, performance, safety, environmental impact, and real-world applications of aluminum air batteries vs. lithium-ion batteries. We’ll also present a detailed comparison table to help you see the differences.

Part 1. Dedicated comparison: Aluminum air battery vs. lithium-ion

| Feature | Aluminum Air Battery | Lithium-Ion Battery |

|---|---|---|

| Rechargeable | ❌ No | ✅ Yes |

| Energy Density | ✅ Up to 8,100 Wh/kg | ❌ ~250 Wh/kg |

| Cost per kWh | ✅ $80–$110 | ❌ $130–$170 |

| Cycles (Lifespan) | ❌ 1 (non-rechargeable) | ✅ 1,000+ cycles |

| Safety | ✅ Very safe | ❌ Risk of fire |

| Environmental Impact | ✅ Low toxicity, recyclable | ❌ High mining impact |

| Maintenance | ❌ High (manual plate change) | ✅ Low (automated systems) |

| EV Suitability | ❌ Limited (range extender only) | ✅ Ideal (main power source) |

| Availability | ❌ Experimental stage | ✅ Widely used |

| Market Adoption | ❌ Low | ✅ High |

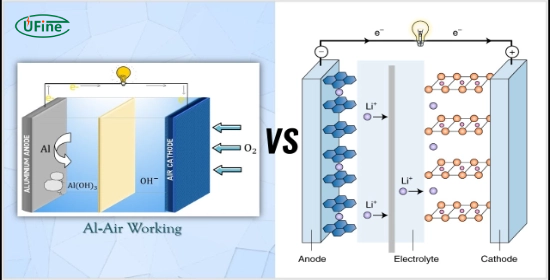

Part 2. Aluminum air battery vs. lithium-ion: What are they and how do they work?

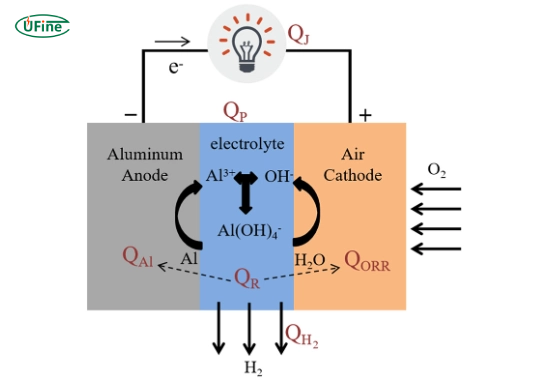

Aluminum Air Battery: How it works

An aluminum air battery is a type of metal-air electrochemical cell. It generates electricity through a chemical reaction between aluminum and oxygen from the air, typically in an electrolyte such as potassium hydroxide or saltwater.

- Anode: Aluminum plate

- Cathode: Ambient air (oxygen)

- Electrolyte: Aqueous solution (often alkaline)

Chemical reaction:

4Al + 3O₂ + 6H₂O → 4Al(OH)₃ + electricity

This type of battery is non-rechargeable, meaning it must be replaced once the aluminum anode is consumed.

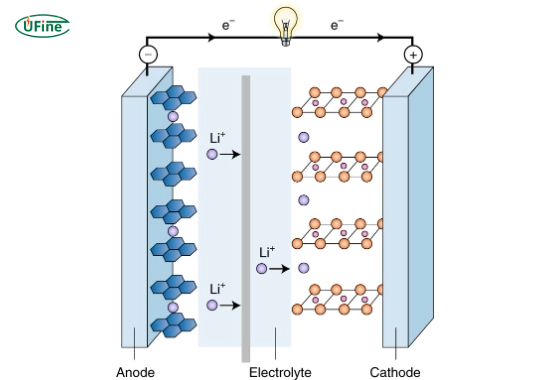

Lithium-Ion Battery: How it works

Lithium-ion batteries are rechargeable electrochemical cells that work by moving lithium ions between a cathode and an anode during charge and discharge cycles.

- Anode: Typically graphite

- Cathode: Lithium metal oxide (like LiCoO₂)

- Electrolyte: Organic solvent with lithium salt

Lithium ions move from the anode to the cathode during discharge, generating an electric current. During charging, the flow is reversed.

Part 3. Aluminum air battery vs. lithium-ion: Energy density and range

Regarding energy density, aluminum air batteries are in a league.

| Battery Type | Gravimetric Energy Density (Wh/kg) | Volumetric Energy Density (Wh/L) |

|---|---|---|

| Aluminum Air (theoretical) | Up to 8,100 Wh/kg | ~6,000 Wh/L |

| Lithium-Ion (NMC) | 150–250 Wh/kg | 400–700 Wh/L |

What does that mean?

- An aluminum air battery can provide over 30 times the energy per kilogram than lithium-ion.

- This could mean driving up to 1,000 miles on a single aluminum cartridge in electric vehicles.

However, since aluminum air batteries can’t be recharged, their practical use is limited.

Part 3. Aluminum air battery vs. lithium-ion: Cost of materials and production

Aluminum: Abundant and affordable

- Aluminum is the third most abundant element on Earth.

- Global cost: ~$2,000 per ton (2024 average)

- It is easily recyclable and low environmental extraction cost

Lithium: Scarce and expensive

- Lithium is a rare metal found in salt flats and hard rock mines.

- Global cost: ~$15,000–$20,000 per ton (fluctuating)

- Extraction is environmentally damaging and energy-intensive

Manufacturing costs

| Battery Type | Estimated Production Cost ($/kWh) |

|---|---|

| Aluminum Air | $80–$110 |

| Lithium-Ion (NMC) | $130–$170 |

While aluminum air batteries have a lower upfront production cost, they lack rechargeability, which affects lifecycle cost.

Part 4. Aluminum air battery vs. lithium-ion: Rechargeability and convenience

This is where lithium-ion batteries shine.

| Feature | Aluminum Air | Lithium-Ion |

|---|---|---|

| Rechargeable | ❌ Not rechargeable | ✅ Rechargeable (1,000+ cycles) |

| Charging Method | Manual aluminum replacement | Plug-and-charge |

| Maintenance | High (replace plates, flush) | Low (battery management systems) |

For daily use in consumer electronics or EVs, convenience matters. Lithium-ion batteries are plug-and-play, while aluminum air batteries require manual intervention.

Part 5. Aluminum air battery vs. lithium-ion: Lifespan and durability

- Cycle Life

Aluminum air: One-time use unless aluminum is replaced

Lithium-ion: 800 to 3,000 charge cycles depending on chemistry - Shelf Life

Aluminum air batteries can last long if unused but degrade once exposed to air and electrolytes.

Lithium-ion batteries experience slow degradation over time, even if not used.

Winner: Lithium-ion due to its reusability and long cycle life.

Part 6. Aluminum air battery vs. lithium-ion: Environmental impact

| Aspect | Aluminum Air | Lithium-Ion |

|---|---|---|

| Material Abundance | ✅ Very high | ❌ Low |

| Toxicity | ✅ Low (aluminum hydroxide) | ❌ High (cobalt, nickel) |

| Recycling Complexity | ✅ Simple | ❌ Complex, expensive |

| Carbon Footprint | ✅ Low | ❌ High (mining & manufacturing) |

Aluminum air batteries are more eco-friendly in terms of raw materials and recyclability. However, the need for constant aluminum replenishment adds a hidden environmental cost over time.

Part 7. Aluminum air battery vs. lithium-ion: Safety and Risk

Lithium-Ion Safety Concerns

- Risk of thermal runaway

- Fire hazard if punctured or overcharged

- Requires cooling systems in EVs

Aluminum Air Safety Benefits

- No flammable electrolytes

- Operates at ambient temperatures

- No risk of explosion or combustion

Conclusion: Aluminum air wins in safety, especially for military, aerospace, and high-risk industrial applications.

Part 8. Aluminum air battery vs. lithium-ion: Suitability for electric vehicles

Lithium-Ion in EVs

- Proven in Tesla, Nissan, BYD, Volkswagen

- Supports fast charging, regenerative braking

- Integrated Battery Management Systems (BMS)

Aluminum Air in EVs

- Tested by companies like Phinergy

- Can extend EV range to 1,000+ miles

- Not rechargeable — aluminum plates must be swapped at service stations

Best use case for aluminum air in EVs: Range extender modules, not primary power source — at least for now.

Part 9. Aluminum air battery vs. lithium-ion: Which is better for the future?

The answer depends on the application.

Aluminum air batteries are ideal for:

- Military and aerospace (where weight and safety matter)

- Backup power systems

- Long-range auxiliary power

Lithium-ion batteries are best for:

- Consumer electronics

- Electric vehicles

- Grid-scale energy storage

If aluminum air technology advances to allow rechargeability or quick metal replacement, it could disrupt the battery market. Lithium-ion remains the dominant technology due to its maturity and convenience.

Part 10. FAQs about aluminum air battery vs. lithium-ion

Is an aluminum air battery better than lithium-ion?

Not always. Aluminum air has higher energy density and is safer. Still, lithium-ion is rechargeable, more convenient, and better supported by infrastructure.

Why aren’t aluminum air batteries common?

Because they’re non-rechargeable and require manual maintenance, making them less practical for daily use.

Can aluminum air batteries be used in smartphones?

No. They are not suitable for small, rechargeable devices that need regular charging.

Are aluminum air batteries safe?

Yes. They are non-flammable, non-toxic, and operate at room temperature.

Will aluminum air batteries replace lithium-ion?

Only if breakthroughs make them rechargeable or easier to refuel. Until then, they have served as complementary technology.

Related Tags:

More Articles

How to Choose the Right 48V Battery for Your E‑Bike?

Choosing the right 48V e-bike battery depends on motor size, usage, chemistry, and safety—this guide helps you make the best decision.

Aluminum Air Battery Design: Materials, Assembly & Efficiency Tips

An aluminum air battery uses aluminum and air to generate power. Learn its materials, assembly steps, and tips to boost energy output and efficiency.

7 Advantages of a Heated Lithium Battery in Cold Climates

Looking to power batteries in freezing temps? Heated lithium batteries excel in cold climates. Here are 7 key benefits and how they work.

How to Choose the Best Floor Scrubber Battery for Commercial Cleaning?

Selecting the ideal floor scrubber battery ensures a long runtime, rapid charging, and minimal maintenance for efficient commercial cleaning operations.

Battery for Blower vs Battery for Leaf Vacuum: Which One Should You Choose?

Battery for blower vs leaf vacuum—learn the key differences in power, fit, and runtime to choose the right battery for your outdoor tool needs.