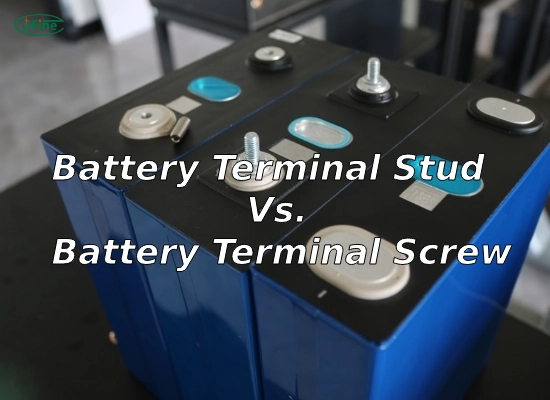

When it comes to ensuring a reliable connection for your vehicle’s battery, the choice between battery terminal studs and battery terminal screws can make a significant difference. These components seem trivial at first glance. Still, they are crucial to your battery system’s overall performance and longevity. In this article, we’ll delve into the details, comparing these two options to help you determine the better choice for your needs.

Part 1. Battery terminals

Battery terminals are the vital connectors that link your vehicle’s battery to its electrical system. These small yet crucial components ensure a consistent and efficient flow of electricity. Without well-functioning battery terminals, your car would struggle to start, and many of its electrical components—like lights, radio, and onboard computer systems—wouldn’t operate effectively.

Part 2. What are battery terminal studs?

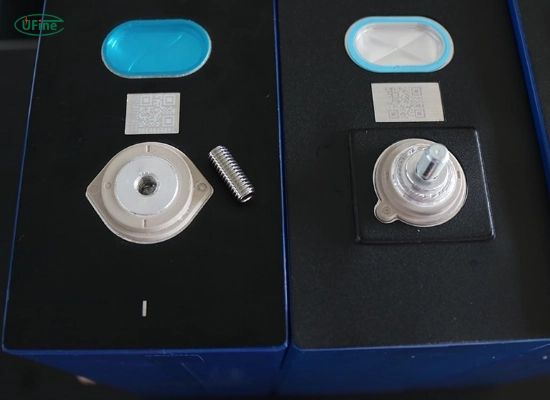

Battery terminal studs are threaded bolts attached to the battery terminals. They provide a secure attachment point for battery cables, ensuring a tight and reliable connection. Studs are typically made of durable materials like brass or stainless steel to resist corrosion and wear.

Advantages of Battery Terminal Studs

Enhanced Durability

Battery terminal studs are known for their durability. Made from robust materials, they are less likely to rust or degrade over time, ensuring a long-lasting connection.

Superior Connection

The threaded design of studs allows for a tighter and more secure connection compared to screws. This tight connection minimizes the risk of loose cables, leading to poor electrical performance or battery failure.

Easy Maintenance

Battery terminal studs are generally easier to maintain. The sturdy construction means they require less frequent replacement, saving you time and effort in the long run.

High Current Capacity

Studs are capable of handling higher current loads compared to screws. This makes them ideal for vehicles with high electrical demands, such as trucks, RVs, or cars with numerous electrical accessories.

Drawbacks of Battery Terminal Studs

Higher Cost

One of the main drawbacks of battery terminal studs is their higher cost compared to screws. The materials and construction quality contribute to the increased price.

Installation Complexity

Installing studs can be more complex and time-consuming. It often requires specific tools and more expertise, which may only be ideal for some.

Part 3. What are battery terminal screws?

Battery terminal screws are fasteners that attach the battery cables to the terminals using a screw mechanism. These screws, often made from metal, allow users to tighten or loosen them to secure the connection.

Advantages of Battery Terminal Screws

Simplicity and Convenience

Battery terminal screws are simple to install and require minimal tools. This makes them convenient for those who prefer a straightforward installation process.

Cost-Effective

Screws are typically more affordable than studs. If you’re on a tight budget, battery terminal screws can be a cost-effective solution without compromising too much on performance.

Flexible Applications

Users can use battery terminal screws in a variety of applications, from small cars to motorcycles. Their versatility makes them a popular choice for many vehicle owners.

Drawbacks of Battery Terminal Screws

Lower Durability

Screws are generally less durable than studs. They are more susceptible to corrosion and wear, which can lead to frequent replacements.

Weaker Connection

The connection provided by screws is typically less secure than that of studs. This can result in loose cables over time, affecting the battery’s overall performance.

Limited Current Capacity

Battery terminal screws have a lower current capacity, which might not be sufficient for vehicles with high electrical demands.

Part 4. How do you choose the correct battery terminals for your device?

When deciding between battery terminal studs and screws, consider the following factors:

Vehicle Type

Battery terminal studs are generally the better choice for heavy-duty vehicles or those with high electrical demands due to their higher current capacity and durability.

Budget

Suppose you’re looking for a more budget-friendly option. In that case, battery terminal screws might be suitable, especially for smaller vehicles with fewer electrical components.

Maintenance

If you prefer a low-maintenance solution, studs are the way to go. They offer long-lasting performance and require less frequent replacements.

Installation

For those who prioritize ease of installation, screws provide a more straightforward and quicker setup process.

Expert Opinions:

Mechanics’ Perspective

Many professional mechanics recommend battery terminal studs for their reliability and superior connection. They argue that the initial investment pays off in the long run with fewer maintenance issues and better performance.

DIY Enthusiasts’ Perspective

On the other hand, DIY enthusiasts often prefer battery terminal screws for their simplicity and cost-effectiveness. They appreciate the ease of installation and the ability to replace them quickly.

Part 5. Battery terminal stud vs battery terminal screw: real-world examples

Off-Road Vehicles

Off-road vehicles, subject to harsh conditions and high electrical loads, often benefit from using battery terminal studs. Their durability and high current capacity ensure the car performs reliably even in extreme environments.

Daily Commuters

For daily commuter vehicles with standard electrical needs, battery terminal screws can be a practical choice. They provide sufficient performance at a lower cost, making them ideal for regular use.

Part 6. FAQs

-

What tools do I need to install battery terminal studs or screws?

To install battery terminal studs or screws, you’ll need a few essential tools. You’ll generally need a wrench or socket set to tighten the nuts for studs. For screws, a screwdriver or a small wrench is usually sufficient. Having a wire brush to clean the battery posts and terminals before installation is also helpful. Safety gear like gloves and eye protection is essential to protect yourself from battery acid and sparks. -

Can I use battery terminal studs and screws interchangeably?

No, you cannot use battery terminal studs and screws interchangeably. Designers create them for different types of batteries and specific uses. Studs are typically used for high-current applications and provide a more secure connection. Screws are more common in standard vehicles and are easier to install. Always use the terminal type that matches your battery and vehicle specifications to ensure proper performance and safety. -

How do I prevent corrosion on battery terminals?

Preventing corrosion on battery terminals is essential for maintaining a good electrical connection. First, clean the terminals by regularly wiping them down with baking soda and water. After cleaning, apply a thin layer of petroleum jelly or a specialized battery terminal protectant spray to prevent corrosion. Ensuring the terminals are tight and secure also helps reduce the risk of corrosion. -

Why do some vehicles use battery terminal studs instead of screws?

Some vehicles use battery terminal studs instead of screws because studs provide a more secure and stable connection. This is especially important in high-performance or heavy-duty vehicles requiring much electrical power. Studs can handle higher current loads and are less likely to come loose, which can prevent electrical issues and improve overall vehicle performance. -

Are there different materials used for battery terminal studs and screws?

Yes, manufacturers can make battery terminal studs and screws from different materials. Common materials include lead, brass, and stainless steel. People often choose lead for its conductivity and ease of use. Brass is more durable and resistant to corrosion. Stainless steel is the most resistant to corrosion but can be more expensive. Choosing the suitable material depends on your vehicle’s needs and the environment in which you drive.

Related Tags:

More Articles

How to Choose the Best Floor Scrubber Battery for Commercial Cleaning?

Selecting the ideal floor scrubber battery ensures a long runtime, rapid charging, and minimal maintenance for efficient commercial cleaning operations.

Battery for Blower vs Battery for Leaf Vacuum: Which One Should You Choose?

Battery for blower vs leaf vacuum—learn the key differences in power, fit, and runtime to choose the right battery for your outdoor tool needs.

How to Choose the Right Battery for Blower?

Choosing the right blower battery? Consider voltage, capacity, chemistry & usage. This guide helps match the best battery for peak performance.

How to Choose the Best Insulated Battery Box for Lithium Batteries?

Choosing the Best Insulated Battery Box for Lithium Batteries? Discover key factors such as size, material, and safety for optimal protection and performance.

7 Critical Elements on a Lithium Battery Shipping Label

What must be on a lithium battery shipping label? Learn 7 key elements to ensure safety, legal compliance, and correct handling across all transport modes.