Why are lithium-ion battery safety standards, such as UN 38.3 and IEC 62133, critical for both transportation and consumer electronics? In today’s rapidly advancing world of consumer electronics and lithium-ion batteries, safety testing standards like UN 38.3 and IEC 62133 are critical for ensuring battery performance, safety, and environmental responsibility. This article provides a detailed comparison of these two globally recognized standards, examining their testing conditions, purposes, and compliance requirements, while highlighting their importance in ensuring the safe transport and use of lithium-ion batteries.

Part 1. Understanding UN 38.3 and IEC 62133 standards for lithium-ion battery safety

The UN 38.3 standard for lithium-ion battery transport and the IEC 62133 standard for portable electronic devices are both essential in ensuring safety, reliability, and compliance in global markets. In this article, we’ll explore these two standards and compare their test conditions.

What is UN 38.3 and Why is it Important for Lithium-ion Battery Transport?

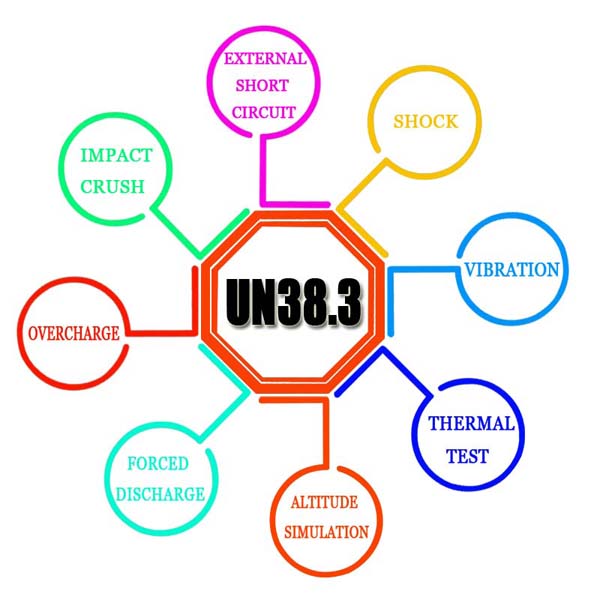

UN 38.3 is a globally recognized standard developed by the United Nations to ensure the safe transportation of lithium-ion batteries. This standard outlines a series of tests designed to simulate real-world transport conditions, such as extreme temperatures, vibration, and altitude changes, to assess whether batteries can safely endure the mechanical and environmental challenges of shipping across air, sea, or land.

The goal of UN 38.3 is to prevent hazards like thermal runaway, short circuits, and leakage during transit. By passing these rigorous tests, batteries demonstrate compliance with international safety regulations, ensuring that they can be safely transported without posing risks to people or property.

What is IEC 62133 and How Does it Ensure Safety for Lithium-ion Batteries in Consumer Electronics?

IEC 62133 is a vital part of battery safety standards. Developed by the International Electrotechnical Commission (IEC), this standard focuses on ensuring the safety of portable sealed secondary lithium cells and batteries. It sets out specific criteria and test methods to evaluate the safety and performance of lithium batteries used in portable electronic devices. Covering electrical, mechanical, and chemical properties, IEC 62133 aims to reduce risks associated with battery use in consumer electronics. This standard ensures that batteries meet strict safety requirements, protecting users from overheating, short circuits, and leakage.

Part 2. UN 38.3 test conditions

2.1 Scope and Purpose

UN 38.3 testing holds paramount importance in ensuring the safe transportation of lithium-ion batteries. The scope of UN 38.3 testing encompasses a wide range of factors crucial for evaluating the safety and reliability of batteries during transport. Its primary purpose is to mitigate potential hazards associated with the transportation of lithium batteries, such as thermal runaway, short circuits, and leakage, thereby safeguarding the integrity of the transport process and protecting both people and property.

2.2 Test Conditions

Batteries are tested for transportability, simulating various environmental conditions such as temperature extremes and altitude fluctuations. The UN 38.3 standard for lithium-ion battery transportation ensures batteries can handle mechanical stresses encountered during air and road transportation.

- Temperature: Batteries are subjected to extreme temperature variations to assess their performance under diverse climatic conditions. Testing involves exposing batteries to high and low temperatures to evaluate their thermal stability and resilience.

- Altitude: Testing under different altitudes simulates the effects of air pressure changes during air transportation. This ensures that batteries can withstand pressure differentials encountered during flights without compromising safety or functionality.

- Vibration: Batteries undergo vibration testing to replicate the mechanical stresses experienced during road or air transport. Vibrational forces help evaluate batteries’ structural integrity and resistance to mechanical damage.

- Shock: Shock testing involves subjecting batteries to sudden impacts or drops, simulating the jolts and bumps encountered during handling and transport. This assesses the battery’s ability to withstand mechanical shocks without rupturing or malfunctioning.

2.3 Compliance Requirements

Here are detailed compliance requirements for batteries to pass UN 38.3 testing:

- Performance Criteria: Batteries must meet specified performance criteria, including capacity retention, voltage stability, and impedance characteristics, throughout the testing process.

- Safety Thresholds: Batteries must not exceed predefined safety thresholds for parameters such as temperature rise, internal pressure, and voltage variation during testing.

- Leakage Prevention: Batteries must demonstrate effective measures to prevent electrolyte or other hazardous materials leakage under different environmental conditions.

- Mechanical Integrity: Batteries should maintain structural integrity and functional performance after exposure to vibration, shock, and other mechanical stress.

- Electrical Insulation: Batteries must exhibit adequate electrical insulation to prevent short circuits or other electrical malfunctions during testing.

- Environmental Impact: Batteries should comply with environmental regulations, including restrictions on hazardous substances such as lead, mercury, and cadmium, to minimize their ecological footprint.

- Documentation and Labeling: Manufacturers must provide comprehensive documentation and labeling indicating compliance with UN 38.3 requirements, including test reports and safety data sheets.

Meeting these compliance requirements ensures that batteries are safe, reliable, and suitable for air, sea, or land transportation, minimizing the risk of accidents or incidents during transit.

Part 3. IEC 62133 test conditions

3.1 Scope and Purpose

The scope of IEC 62133 testing encompasses the safety requirements for portable sealed secondary lithium cells and batteries used in various electronic devices. Its purpose is to ensure that batteries meet stringent safety standards to mitigate potential risks of using portable electronic devices. This includes preventing hazards such as thermal runaway, short circuits, overcharging, and leakage, thereby enhancing the safety and reliability of battery-powered devices for consumers.

3.2 Test Conditions

IEC 62133 testing evaluates a wide range of performance criteria, including electrical and mechanical factors, to ensure that lithium-ion batteries are safe for use in consumer electronics like smartphones, laptops, and cameras.

- Temperature: Batteries undergo testing at different temperature extremes to assess their performance under varying climatic conditions. This ensures that batteries can operate safely and reliably across a wide temperature range.

- Humidity: Testing under controlled humidity levels evaluates the battery’s ability to withstand moisture and humidity, which can impact its performance and safety, especially in humid environments.

- Mechanical Testing: Batteries are subjected to mechanical stress tests, including compression, impact, and vibration, to assess their structural integrity and resistance to physical damage during use and transportation.

- Electrical Testing: Various electrical tests, such as capacity measurement, charge/discharge cycling, and impedance analysis, are conducted to evaluate the battery’s electrical performance, efficiency, and reliability.

3.3 Compliance Requirements

Batteries must comply with stringent requirements outlined in the standard of IEC 62133 testing to pass it. These compliance requirements include:

- Safety Standards: Batteries must meet specified safety standards to prevent hazards such as thermal runaway, short circuits, and overcharging, ensuring user safety during operation.

- Performance Criteria: Batteries must demonstrate consistent performance, including stable voltage output, capacity retention, and cycle life, under different operating conditions.

- Labeling and Documentation: Manufacturers must provide proper labeling and documentation indicating compliance with IEC 62133 requirements, including test reports, safety data sheets, and product certifications.

Part 4. Comparison of UN 38.3 and IEC 62133

When considering battery safety testing standards, it’s essential to understand the distinctions between UN 38.3 and IEC 62133. Let’s delve into the comparison:

Scope and Application

- UN 38.3: Primarily focuses on ensuring the safe transportation of lithium-ion batteries across various transport modes, including air, sea, and land. It addresses specific concerns such as temperature extremes, pressure changes, vibration, and shock that batteries may experience during transit.

- IEC 62133: This standard is dedicated to ensuring the safety of lithium-ion batteries in consumer electronic devices like smartphones, laptops, and cameras. It assesses performance in a range of environmental conditions, ensuring that batteries are safe for everyday use by consumers.

Test Conditions

- While both standards involve environmental testing, UN 38.3 focuses on transportation hazards like vibration, altitude, and shock. IEC 62133 encompasses a wider range of conditions, including humidity, electrical performance, and mechanical durability, ensuring batteries perform safely in everyday consumer products.

Compliance Requirements

- Batteries passing UN 38.3 ensure safe transport without risk of leaks or fire. Batteries meeting IEC 62133 demonstrate safety in everyday use, reducing the risk of overcharging or thermal runaway in portable devices.

Certification Process

- UN 38.3: Manufacturers typically need UN 38.3 certification to demonstrate compliance with transportation regulations for batteries intended for transportation.

- IEC 62133: Certification is essential for batteries used in consumer electronic devices, with manufacturers obtaining IEC 62133 certification to verify compliance with safety standards for consumer products.

Part 5. FAQs

-

What is the difference between UL 1642 and IEC 62133?

The distinction between UL 1642 and IEC 62133 lies in their focus and purpose. UL 1642 primarily tests the safety of lithium batteries for various applications, while IEC 62133 specifically ensures the safety of lithium batteries in portable electronic devices. -

What is the difference between UL 2054 and IEC 62133?

Similarly, UL 2054 and IEC 62133 differ in their target devices and emphasis. UL 2054 concentrates on battery safety in consumer products like household appliances and power tools, whereas IEC 62133 focuses on lithium battery safety in portable electronic devices such as smartphones and laptops. -

Is IEC 62133 mandatory?

Although IEC 62133 is not legally mandatory in all jurisdictions, manufacturers often comply with its standards to demonstrate the safety and reliability of lithium batteries in portable electronic devices, especially for market approval and certification purposes. -

Which battery safety standard should I follow for my product?

Depending on your product’s application, the appropriate safety standard may vary. If your product involves the transport of lithium-ion batteries, UN 38.3 certification is necessary to ensure compliance with international transportation regulations. On the other hand, if your product uses portable lithium batteries in consumer electronics, compliance with IEC 62133 ensures safety standards are met for safe operation in daily use. -

What is the difference between IEC 62133 and 62133-2?

The distinction between IEC 62133 and IEC 62133-2 lies in their specific focus and scope. While IEC 62133 outlines safety requirements for lithium batteries in portable electronic devices, IEC 62133-2 specifically addresses safety requirements for lithium batteries used in equipment for potentially explosive atmospheres.

Related Tags:

More Articles

Lithium Ion Jump Starter vs. Lead Acid: What’s the Real Difference?

A lithium-ion jump starter offers a fast, reliable way to start a dead car battery. Here's how it compares to traditional lead-acid models.

How to Safely Clean Leads from a Leaking Battery: Step-by-Step Guide

This step-by-step guide covers risks, safety tips, and proper cleaning methods for safely cleaning leads from a leaking battery.

Portable Battery Charger vs. Power Bank: What’s the Difference?

A portable battery charger includes any portable charging device, while a power bank stores energy in a battery to charge devices without a power source.

The Ultimate Guide to Using a Lithium-Ion Jump Starter

A lithium-ion jump starter is essential for car emergencies. This guide covers its use, safety, maintenance, and why it's a smart investment.

What Is a Portable Battery Charger?

A portable battery charger keeps devices powered on the go. This guide covers its definition, materials, and how it works for easy understanding.