In today’s fast-paced technological landscape, innovation is the key driving force behind the electronics industry. One of the most cutting-edge advancements is the development of curved batteries. These batteries are not just an improvement in battery technology; they represent a paradigm shift in how we think about powering devices. This comprehensive guide will explore curved batteries’ characteristics, applications, and customization options, providing an in-depth understanding of this revolutionary technology.

Part 1. What is a curved battery?

A curved battery is an energy storage device that can be bent or shaped to fit into various form factors, unlike traditional rigid batteries. This flexibility is achieved through advanced materials and innovative engineering, allowing the battery to maintain its performance even when bent.

Part 2. What technology makes curved batteries?

Making curved batteries involves several key steps. Each step ensures the battery is flexible, durable, and efficient. Let’s dive into the process in detail.

1. Material Selection

The first step is choosing the suitable materials. Curved batteries use unique materials that can bend without breaking. Common materials include:

- Graphene: This material is strong and flexible. It conducts electricity well.

- Flexible Polymers: These are plastic-like materials that can bend easily.

- Thin-Film Technology: This involves layering fragile materials to make the battery flexible.

2. Electrode Preparation

Next, we prepare the electrodes. Electrodes are the parts of the battery that store and release energy. Here’s how we make them:

- Coating: We coat a thin active material (like lithium) onto a flexible substrate (a base layer that can bend).

- Drying: The coated substrate is dried to remove any solvents.

- Cutting: We cut the dried material into the desired shapes and sizes.

3. Electrolyte Application

The electrolyte is the substance that allows ions to move between the electrodes. For curved batteries, the electrolyte must also be flexible. The process includes:

- Choosing a Flexible Electrolyte: Gel or solid-state electrolytes are common because they can bend.

- Applying the Electrolyte: We use the electrolyte in a thin, even layer over the electrodes.

4. Assembly of Battery Layers

The battery is then assembled by layering the materials together. This process involves:

- Stacking the Layers: We stack the anode (negative electrode), electrolyte, and cathode (positive electrode) in a specific order.

- Laminating: We press the layers together to ensure good contact and flexibility.

5. Encapsulation

Encapsulation involves sealing the battery to protect it from the environment. This step is crucial for preventing leaks and ensuring safety. It includes:

- Sealing: We seal the battery in a flexible, waterproof material.

- Testing for Leaks: We test the sealed battery to ensure no leaks.

6. Charging and Testing

Finally, the battery is charged and tested. This ensures it works correctly and meets performance standards. The steps are:

- Initial Charging: The battery is charged for the first time to activate the materials.

- Performance Testing: We test the battery for capacity, flexibility, and safety.

7. Final Inspection and Packaging

The last step is inspecting the battery and preparing it for shipment. This involves:

- Quality Inspection: We inspect each battery to ensure it meets quality standards.

- Packaging: We package the batteries in materials that protect them during shipping.

Part 3. Characteristics of curved batteries

1. Flexibility

The most distinguishing feature of curved batteries is their flexibility. They can be bent, twisted, and shaped without losing their functionality. This flexibility is possible using graphene, flexible polymers, and thin-film technologies.

2. Lightweight and Thin

Curved batteries are lightweight and thin, ideal for portable and wearable electronics. Their slim profile does not compromise energy density, allowing for powerful yet compact energy solutions.

3. Durability

Despite their flexible nature, we design curved batteries to be durable. They can withstand repeated bending and twisting without degrading performance, making them reliable for long-term use.

4. High Energy Density

Curved batteries boast a high energy density, meaning they can store significant energy in a small volume. This is crucial for limited-space applications, such as wearables and compact devices.

5. Safety

Safety is paramount in battery technology. We engineer curved batteries to be safe, incorporating features like thermal management, short-circuit protection, and leak-proof designs to prevent accidents.

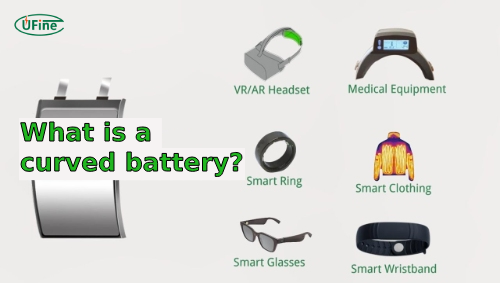

Part 4. Applications of curved batteries

1. Wearable Technology

One of the most prominent applications of curved batteries is in wearable technology. Devices like smartwatches, fitness trackers, and health monitors benefit immensely from curved batteries’ flexibility and lightweight nature, allowing for more comfortable and ergonomic designs.

2. Flexible Electronics

Curved batteries are essential for flexible electronics like foldable smartphones, tablets, and rollable displays. These batteries enable the creation of devices that can change shape without compromising the power supply.

3. Medical Devices

In medicine, curved batteries power advanced medical devices like flexible sensors, implantable devices, and portable diagnostic tools. Their biocompatibility and flexibility make them suitable for use in sensitive medical environments.

4. Smart Textiles

Integrating curved batteries into smart textiles opens up new possibilities for wearable technology. These textiles can include embedded sensors and electronics powered by flexible batteries, enabling innovations in fashion, health monitoring, and more.

5. Consumer Electronics

From smartphones to laptops, curved batteries are finding their way into traditional consumer electronics, enhancing the design and functionality of these devices. Their ability to conform to different shapes allows for more innovative and ergonomic product designs.

6. Automotive Industry

Researchers and engineers are exploring curved batteries in electric vehicles (EVs) and hybrid vehicles in the automotive industry. Their flexibility allows them to be integrated into various vehicle parts, optimizing space and weight distribution.

Part 5. Customization of curved batteries

1. Size and Shape Customization

One of the significant advantages of curved batteries is the ability to customize their size and shape. Manufacturers can design batteries to fit specific device form factors, ensuring optimal use of space and enhancing device aesthetics.

2. Capacity Customization

We can tailor curved batteries to meet different capacity requirements. Whether a device needs a high-capacity battery for extended usage or a smaller one for a compact design, customization options are available to meet these needs.

3. Voltage Customization

Different applications require different voltage levels. Curved batteries can be customized to provide the necessary voltage for various devices, ensuring compatibility and optimal performance.

4. Material Customization

We can customize the materials used in curved batteries to achieve specific performance characteristics. For instance, graphene can enhance conductivity, while flexible polymers can improve durability.

5. Integration with Other Components

We can design curved batteries to integrate seamlessly with other electronic components. This integration reduces the need for additional connectors and wiring, simplifying the overall device design and improving reliability.

Part 6. FAQs

-

Can I bend the battery?

No, it would be best not to bend the battery by yourself. We make curved batteries to fit specific devices and their shapes. Bending them yourself can damage the battery and make it unsafe to use. -

How long do curved batteries last?

Curved batteries last about 2 to 3 years with regular use. Their lifespan can vary based on how often you charge and use them. Taking good care of them, such as avoiding overcharging, can help curved batteries last longer. -

Are curved batteries safe?

Yes, curved batteries are safe when used correctly. Manufacturers test them to meet safety standards. Avoid dropping, puncturing, or exposing them to extreme temperatures to keep them safe. -

Can curved batteries be recycled?

Yes, recyclers can recycle curved batteries. Take them to a proper recycling center that handles batteries. This helps protect the environment and recover valuable materials.

Related Tags:

More Articles

What You Need to Know About AA 3.6V Lithium Battery

Learn all about AA 3.6V lithium batteries—voltage, size, capacity, uses, and the best replacements. Discover why they’re powerful, and highly reliable.

What Are Lithium Salts and Why They Matter in Battery Electrolytes

Lithium salts in electrolytes are key to battery performance, powering everything from phones to EVs and shaping the future of clean energy.

Lithium AAA Battery Guide: Power, Performance & Chargers

Explore lithium AAA batteries—voltage, capacity, weight, top brands, and more. Learn how to choose the best battery for your device and why it really matters.

How to Calculate Watts, Volts, and Amps (With Simple Formulas and Examples)

Learn how to calculate watts, volts, and amps for lithium batteries with simple formulas and examples, ideal for EVs, solar, and energy systems.

Comprehensive Analysis of U.S. Tariffs on Chinese Lithium Batteries

U.S. tariffs on Chinese lithium batteries in 2025 impact costs, supply chains, and EV, energy storage, and electronics industries globally.