The working performance of lithium batteries is greatly affected by temperature. Especially in low temperature environments, its performance and safety will be seriously affected.

Part 1. The harm of low temperatures to lithium batteries

1. Capacity and energy density

In low temperature environments, the capacity and energy density of lithium batteries will be significantly reduced. This is because the viscosity of the electrolyte increases, and the ion conduction speed slows down, reducing the transmission efficiency of lithium ions in the electrolyte.

2. Charging and discharging efficiency

When charging at low temperatures, the charging efficiency of lithium batteries decreases, which may result in incomplete charging. During discharge, the discharge efficiency will also be affected due to the reduction in ion conduction speed.

3. Cycle life

Low-temperature charging and discharging can negatively impact the cycle life of lithium batteries. Due to the electrolyte’s decomposition and lithium metal deposition, the battery capacity will gradually decrease, and the cycle life will be shortened.

4. Safety performance

In low temperature environments, the safety performance of lithium batteries will also be affected. In the case of overcharging or overdischarging, the battery may undergo thermal runaway, generating high temperature and high pressure, causing the battery to catch fire or explode.

Part 2. 4 factors affecting the low-temperature performance of Li-ion batteries

The harm of low temperature to lithium batteries was described earlier. But how do low temperatures affect lithium batteries?

Lithium-ion batteries mainly comprise positive electrode materials, harmful electrode materials, separators, and electrolytes. Lithium-ion batteries in low-temperature environments have the characteristics of reduced discharge voltage platform, low discharge capacity, rapid capacity fading, and poor rate performance.

The main factors that restrict the low-temperature performance of Li-ion batteries are as follows.

1. Positive electrode structure

The cathode material’s three-dimensional structure restricts lithium ions’ diffusion rate, and the effect is pronounced at low temperatures. The cathode materials of lithium-ion batteries include lithium iron phosphate, nickel cobalt manganese ternary materials, lithium manganate, lithium cobalt oxide, etc., as well as high-voltage cathode materials in the development stage, such as lithium nickel manganese oxide, lithium iron manganese phosphate, and vanadium phosphate. Lithium etc.

Different cathode materials have different three-dimensional structures. The cathode materials used in electric vehicle power batteries are mainly lithium iron phosphate, nickel cobalt manganese ternary materials, and lithium manganate.

Someone studied the discharge performance of lithium iron phosphate batteries and nickel-cobalt-manganese ternary batteries at -20°C. The discharge capacity of lithium iron phosphate battery at -20°C was found to reach only 67.38% of the normal temperature capacity. The nickel-cobalt-manganese ternary battery can reach 70.1%. Some studies have found that the discharge capacity of lithium manganate batteries at -20°C can reach 83% of the normal temperature capacity.

2. High melting point solvent

Due to high melting point solvents in the electrolyte mixed solvent. The viscosity of lithium-ion battery electrolytes increases in low-temperature environments. When the temperature is too low, the electrolyte solidification phenomenon occurs, reducing the transmission rate of lithium ions in the electrolyte.

3. Lithium ion diffusion rate

The diffusion rate of lithium ions in graphite anode decreases in low-temperature environments. Some studies have pointed out that the charge migration resistance of lithium-ion batteries increases in low temperature environments, resulting in a decrease in the diffusion rate of lithium ions in the graphite anode. This is an important reason affecting the low-temperature performance of lithium-ion batteries.

4. SEI membrane

In low-temperature environments, the SEI film of the negative electrode of lithium-ion batteries thickens. The increase in resistance of the SEI film causes the conduction rate of lithium ions in the SEI film to decrease. Eventually, lithium-ion batteries will form polarization during charging and discharging in low-temperature environments, reducing charging and discharging efficiency.

Part 3. How should I protect lithium batteries at low temperatures?

1. Heating system

In low-temperature environments, a heating system can be introduced to improve the working efficiency of lithium batteries. Through heating devices or heating elements such as thermistors, the battery temperature can be effectively increased, thereby improving the fluidity of the electrolyte and increasing the ion conduction speed.

However, the design of the heating system requires precise temperature control to prevent overheating and damage to the battery.

2. Optimize battery management

Optimizing the battery management system (BMS) is an important way to improve lithium batteries’ performance in low-temperature environments. BMS can precisely control the charging and discharging process of the battery to prevent overcharging and over-discharging.

In addition, BMS can also monitor the battery temperature in real-time to prevent the battery from working in a low-temperature environment.

3. Choose low-temperature resistant battery materials

Choosing low-temperature-resistant electrolyte and separator materials is an effective way to improve the performance of lithium batteries in low-temperature environments. These materials can maintain better fluidity and ion conductivity at lower temperatures. However, this requires the development of new battery materials, increasing R&D costs and time.

4. Warm up the battery

Preheating the battery is a method of heating the battery before use. Preheating can effectively increase the battery temperature, improve the fluidity of the electrolyte, and increase the ion conduction speed.

Preheating methods can be achieved through external heating, battery self-heating, etc.

It should be noted that too long a warm-up time or too high a temperature may cause damage to the battery.

Part 4. Ufine low temperature lithium battery

Ufine Battery further improves the discharge capacity of lithium-ion batteries in low-temperature environments through its unique technology to optimize low-temperature lithium battery electrolytes and low-temperature modification of positive and negative electrode materials.

Discharge rate and service life. Ufine’s low-temperature battery can be used normally in low-temperature environments below -60°C.

As a world-renowned lithium-ion battery manufacturer, Ufine can customize lithium batteries’ size, specification, and appearance according to customer needs.

Part 5. Conclusion

Many factors affect the low-temperature performance of lithium-ion batteries. Low temperature limits the application of lithium-ion batteries in electric vehicles, the military industry, and extreme environments. The development of low-temperature lithium-ion batteries with excellent performance is an urgent need in the market. Ufine will continue to delve into the research and development of low-temperature lithium batteries.

Related Tags:

More Articles

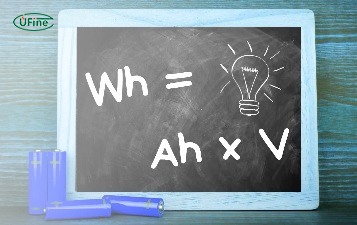

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries, how to calculate battery watt hours, and what Wh means for car batteries, devices, and energy storage.

A Complete Guide to the Best Batteries for Flashlights

Compare the best batteries for flashlights, including AA, AAA, 18650, 21700, CR123A. See which battery offers the best brightness, runtime, and reliability.

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

How Much Current Can a 9V Battery Really Supply?

Discover how many amps a 9V battery can supply, its actual current output, discharge rate, and capacity for alkaline, lithium, and rechargeable 9V batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.