In the world of lithium batteries, ensuring top-notch performance and reliability is essential. Batteries power everything from smartphones to electric vehicles, so they must be rigorously tested before reaching the market. Among various testing methods, Functional Circuit Testing (FCT) is one of the most effective ways to evaluate a battery’s functionality and reliability.

This article provides an in-depth look at what FCT is, how it works, and why it is critical for quality assurance. We’ll also highlight how top manufacturers, such as Ufine Battery, incorporate FCT into their production processes to ensure their lithium batteries meet the highest standards.

Part 1. What is functional circuit testing (FCT)?

Functional Circuit Testing, commonly known as FCT, is a process used to evaluate the functionality, performance, and reliability of electronic circuits. Think of it as a diagnostic tool that confirms whether all parts of a battery are operating as intended.

At its core, FCT leverages the principles of current transformers. These devices convert high electrical currents within a circuit into smaller, measurable signals that can be analyzed for irregularities. By carefully studying these signals, FCT detects issues like short circuits, breaks, or abnormal behaviors.

Additionally, FCT doesn’t stop at just current analysis. It often includes supplementary evaluations such as voltage measurement, resistance testing, and signal analysis. This comprehensive approach ensures that the battery is thoroughly examined from every possible angle.

Part 2. Why is FCT crucial for lithium batteries?

Lithium batteries are used in devices where safety and performance cannot be compromised. FCT testing is crucial because it guarantees that the batteries meet strict quality standards. Here’s why FCT is so important:

-

Performance Verification

- FCT ensures that a battery delivers its intended capacity, voltage, and power under various operating conditions.

-

Safety Assurance

- Faults such as insulation breakdown or irregular voltage can cause overheating, fires, or even explosions. FCT identifies and resolves these issues during production.

-

Long-Term Durability

- By simulating real-world operating conditions, FCT tests how well a battery will perform over time.

-

Cost Efficiency

- Early detection of defects prevents expensive recalls and replacements, saving both time and money.

-

Consumer Trust

- For brands like Ufine Battery, rigorous testing demonstrates their commitment to delivering safe, high-quality products.

15 FAQs About Battery Manufacturing Safety Testing

Part 3. The different control modes in FCT

FCT can be executed using various control methods. Each approach has unique advantages, making them suitable for specific scenarios.

-

MCU (Microcontroller Unit) Control

- Features high-speed operation and precision timing.

- Ideal for custom testing requirements where exact control is necessary.

- Requires specialized circuit designs and tailored programming.

-

Embedded CPU Control

- Offers flexibility and customization for lithium battery testing.

- Allows quick updates to adapt to changing testing needs.

- Works well for complex test setups.

-

PC-Based Control

- A popular and affordable option.

- Provides user-friendly software interfaces for test configuration, monitoring, and result analysis.

- Ideal for environments where intuitive operation is prioritized.

-

PLC (Programmable Logic Controller) Control

- Known for its robustness and reliability.

- Commonly used in industrial testing environments with stringent stability requirements.

- Suitable for complex, multi-step testing processes.

Part 4. What does FCT measure?

FCT covers a wide range of tests to comprehensively assess a lithium battery’s performance and reliability. Below are some of the most critical tests performed during FCT:

-

Insulation Testing

- Checks the insulation between the battery’s positive and negative terminals and its casing.

- Prevents electrical leakage, ensuring user safety and battery longevity.

-

High-Voltage Testing

- Applies a voltage higher than the battery’s normal operating level to test its ability to withstand sudden voltage spikes.

- Helps verify the durability of insulation materials.

-

Resistance Testing

- Measures both internal resistance and electrode contact resistance.

- Internal resistance affects the battery’s charging and discharging efficiency.

- Contact resistance reflects the quality of the assembly process.

-

Load Testing

- Simulates real-world operating conditions to evaluate the battery’s stability under different loads.

- Checks for consistent output of voltage, current, and power.

-

Hall Effect Testing

- For batteries with Hall sensors, this test ensures accurate current measurements.

- Verifies that the battery management system (BMS) is functioning correctly.

-

Phase Loss Detection

- Ensures all phases in multi-phase battery systems are connected and functioning properly.

Part 5. How is FCT testing performed?

The FCT process involves several detailed steps to ensure thorough and accurate testing:

-

Instrument Setup

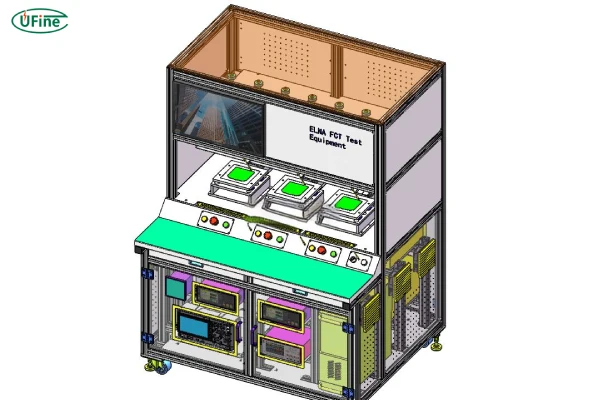

- The battery is carefully connected to the testing equipment. Proper connections are critical to ensure accuracy and avoid damage to the device or equipment.

-

Test Initialization

- Using advanced software platforms like ATECLOUD, technicians select specific tests or a full suite of tests for the battery.

-

Data Collection

- The system monitors key parameters such as voltage, current, and resistance in real time during the test.

-

Data Processing

- Raw data is cleaned and calibrated to remove noise and correct measurement errors.

-

Data Analysis

- Collected data is analyzed to identify trends, detect anomalies, and compare results against standard thresholds.

-

Result Reporting

- Findings are presented in clear, easy-to-understand formats, such as graphs and charts, for quick review.

By following these steps, manufacturers like Ufine Battery ensure that every battery is rigorously tested for reliability and safety.

Part 6. Why FCT is a cornerstone of Ufine Battery’s quality assurance

For a leading brand like Ufine Battery, FCT testing is more than just a quality control step—it’s a commitment to excellence. By investing in state-of-the-art testing equipment and expertise, Ufine Battery ensures that its products perform flawlessly in any application. Whether it’s powering an electric vehicle or providing energy for industrial systems, their batteries undergo thorough FCT to meet the highest industry standards.

Part 7. The tuture of FCT testing

As lithium battery technology evolves, FCT testing will also advance. Emerging trends include the use of AI for real-time diagnostics, machine learning for predictive failure analysis, and advanced simulation tools to replicate extreme conditions.

In summary, FCT testing is a vital part of ensuring lithium battery quality and safety. With its detailed evaluations and reliable processes, it allows manufacturers to deliver products that meet the growing demands of modern consumers and industries.

Related Tags:

More Articles

Is a 3000 mAh Lithium Battery Enough for Your Device?

Wondering what a 3000mAh battery means? Learn about its power, lifespan, types, and how to choose the best one for your device!

Learn About Lithium Battery Kits

Discover the ultimate guide to lithium battery kits—types, safety, installation, and cost analysis. Make the right choice for solar, RV, or off-grid power!

Selecting the Perfect Ah for Your 48V Li-ion Battery Pack

Struggling to choose the right Ah for your 48V Li-ion battery pack? This in-depth guide covers everything you need to make the best choice. Find out more now!

LiFePO4 Pouch Cells Explained: Advantages, Applications & Comparison

Learn all about LiFePO4 pouch cells, their structure, lifespan, advantages, and how they outperform other lithium battery types. Make the right choice!

12Ah Lithium Battery Guide: Uses, Lifespan & Tips

12Ah lithium batteries last longer, charge faster & weigh less than lead-acid. See best uses, charging tips & how to extend lifespan!