- Part 1. What are lithium battery cells?

- Part 2. Why does the quality of lithium battery cells matter?

- Part 3. What materials are used in high-quality lithium battery cells?

- Part 4. How are high-quality lithium battery cells manufactured?

- Part 5. What testing ensures the quality of lithium battery cells?

- Part 6. What are the applications of high-quality lithium battery cells?

- Part 7. How do high-quality lithium batteries ensure sustainability?

- Part 8. What are the top benefits of high-quality lithium battery cells?

- Part 9. FAQs

Lithium battery cells have become integral to modern technology, powering everything from smartphones and laptops to electric vehicles and renewable energy storage systems. However, not all lithium battery cells are created equal. High-quality lithium battery cells stand out due to their superior performance, reliability, and safety. But what exactly sets them apart? In this article, we’ll explore the key factors differentiating premium lithium battery cells from lower-quality alternatives, exploring the materials, manufacturing processes, and testing methods that ensure excellence.

Part 1. What are lithium battery cells?

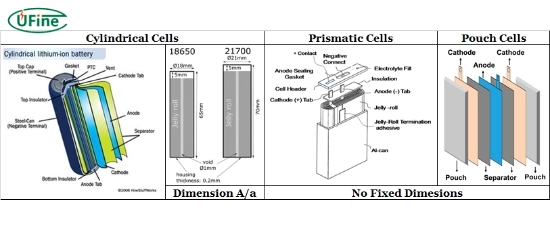

Lithium battery cells are electrochemical energy storage devices that use lithium-ion technology to store and release energy. Each cell consists of a positive electrode (cathode), a negative electrode (anode), an electrolyte, and a separator. Lithium ions move between the cathode and anode when the battery charges or discharges, creating an electrical current.

Lithium battery cells are widely used for their high energy density, long cycle life, and lightweight design. However, the quality of these cells can vary significantly depending on the materials used, manufacturing precision, and testing standards.

Part 2. Why does the quality of lithium battery cells matter?

High-quality lithium battery cells offer several distinct advantages:

- Safety: Inferior batteries are more prone to overheating, swelling, or even catching fire.

- Performance: Premium cells have better energy storage capacity, higher discharge rates, and longer lifespans.

- Reliability: High-quality cells maintain consistent performance even under demanding conditions.

- Sustainability: They are often manufactured with better recycling and environmental practices.

For applications like electric vehicles, aerospace, and medical devices, where failure is not an option, the quality of lithium battery cells is critical.

Part 3. What materials are used in high-quality lithium battery cells?

The materials used in lithium battery cells play a significant role in determining their quality. Here’s a breakdown of the key components:

- Cathode materials: The cathode is the positive electrode and a critical component in determining energy capacity and voltage. High-quality batteries often use advanced cathode materials like:

- Lithium Nickel Manganese Cobalt Oxide (NMC): Known for its high energy density and balanced performance.

- Lithium Iron Phosphate (LFP): Offers excellent thermal stability and safety.

- Lithium Cobalt Oxide (LCO): Common in consumer electronics for its high energy density.

- Anode materials: The anode, or negative electrode, is typically made from graphite. High-quality cells use high-purity graphite that facilitates efficient lithium-ion intercalation, ensuring fast charging and long cycle life. Silicon is also being incorporated into anodes in cutting-edge batteries to boost energy capacity.

- Electrolytes: The electrolyte facilitates the movement of lithium ions between the cathode and anode. High-quality batteries use stable and pure electrolytes to minimize side reactions and ensure safety.

- Separators: The separator is a thin membrane that prevents direct contact between the cathode and anode while allowing ion flow. Advanced separators with high thermal resistance and mechanical strength are essential for safety and performance.

Part 4. How are high-quality lithium battery cells manufactured?

Manufacturing plays a pivotal role in the quality of lithium battery cells. Here’s an overview of the essential steps:

- Materials preparation: The process begins by preparing active materials for the cathode, anode, and electrolyte. High-quality manufacturers use automated systems and rigorous quality control to ensure consistency.

- Electrode coating: The active materials are coated onto metallic foils (aluminum for the cathode and copper for the anode). Uniform coating thickness and adhesion are critical for performance.

- Cell assembly: The coated electrodes are cut, stacked, or wound into cylindrical, pouch, or prismatic shapes. To prevent contamination, cleanroom environments are used.

- Electrolyte filling: The electrolyte is injected into the cell under strict conditions to ensure uniform distribution.

- Sealing and formation: The cell is sealed and undergoes a “formation process,” where it is charged and discharged, controlled to stabilize the internal structure.

- Quality inspection: Every cell is subjected to comprehensive testing to detect defects, measure capacity, and ensure compliance with safety standards.

Part 5. What testing ensures the quality of lithium battery cells?

Testing is a cornerstone of high-quality lithium battery production. Leading manufacturers perform extensive tests at every stage of production to ensure reliability and safety:

- Capacity and energy density testing: This measures how much energy the cell can store and deliver. High-quality cells consistently meet or exceed their rated capacity.

- Cycle life testing: Cells are repeatedly charged and discharged to simulate real-world usage. Premium cells maintain performance over hundreds or thousands of cycles.

- Thermal testing: Cells are exposed to high and low temperatures to perform reliably in extreme conditions.

- Safety testing: Tests such as overcharge, short-circuit and crush ensure the battery can withstand accidents without catching fire or exploding.

- Internal resistance testing: Lower internal resistance indicates better efficiency and heat management. This is a key metric for high-performance batteries.

Part 6. What are the applications of high-quality lithium battery cells?

High-quality lithium battery cells are used in a wide range of applications, including:

- Electric vehicles (EVs): These cells power EVs, offering long-range, fast charging and safety.

- Renewable energy storage: Lithium batteries store energy from solar panels and wind turbines, providing reliable backup power.

- Consumer electronics: Smartphones, laptops, and wearable devices rely on premium cells for compact and long-lasting power.

- Medical devices: High-quality cells ensure reliability and safety in life-critical devices like pacemakers and defibrillators.

- Aerospace and defense: Due to their performance and durability, lithium batteries are used in satellites, drones, and military equipment.

Part 7. How do high-quality lithium batteries ensure sustainability?

Premium manufacturers are increasingly prioritizing sustainable practices, including:

- Using recyclable materials in battery components.

- Employing energy-efficient manufacturing processes.

- Investing in battery recycling programs to recover valuable raw materials like lithium, cobalt, and nickel.

- Reducing reliance on conflict minerals and adopting ethical sourcing practices.

Part 8. What are the top benefits of high-quality lithium battery cells?

To sum up, here are the main advantages of high-quality lithium battery cells:

- Enhanced safety: Reduced risk of thermal runaway or fire.

- Long lifespan: More charge-discharge cycles before degradation.

- Superior performance: Higher capacity, faster charging, and consistent output.

- Reliability: Consistent performance in extreme conditions.

- Environmental friendliness: Better recycling and ethical sourcing.

Top 5 Benefits of Choosing High-Quality Lithium Battery Cells for Your Products

Part 9. FAQs

-

What is the lifespan of a high-quality lithium battery cell?

High-quality lithium battery cells can last between 500 to 3000 charge cycles, depending on the chemistry and usage conditions. For example, LFP batteries tend to have longer lifespans than NMC batteries. -

Why do some lithium batteries catch fire?

Lithium batteries may catch fire due to thermal runaway, a chain reaction triggered by overheating, internal short circuits, overcharging, or physical damage. High-quality batteries include safety mechanisms to prevent such incidents. -

Are high-quality lithium batteries worth the cost?

Yes, high-quality lithium batteries offer better performance, longer lifespan, and enhanced safety, making them a cost-effective choice in the long run. -

How can I identify a high-quality lithium battery?

Look for batteries from reputable manufacturers, check technical specifications (like cycle life and energy density), and verify safety certifications such as UL, IEC, or UN38.3. -

What’s the best battery chemistry for electric vehicles?

NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) are two popular choices for EVs. NMC offers higher energy density, while LFP provides better safety and durability.

Related Tags:

More Articles

Lithium-Ion vs Lead-Acid AMR & AGV Batteries Compared

Discover the pros and cons of lithium-ion and lead-acid AMR & AGV batteries. Learn about cost, lifespan, safety, and which is right for your fleet.

Robot Vacuum Battery Replacement: Easy Step-by-Step Guide

Learn how to replace a robot vacuum battery safely and easily. Step-by-step instructions, battery types, costs, and common mistakes to avoid.

Discover how to choose the right battery for your robot. Compare Li-ion, LiFePO₄, NiMH, and more for performance, safety, and cost.

Inside Humanoid Robot Battery Pack Design

A deep dive into humanoid robot battery pack design, covering battery life, voltage, capacity, safety, and real-world engineering trade-offs.

Humanoid Robot Battery Life: How Long Do They Really Last?

Most humanoid robots run 1.5–4 hours per charge. Learn real-world battery life, battery types, capacity limits, and future improvements.