- Part 1. What is a forklift battery?

- Part 2. Types of forklift batteries

- Part 3. How long does it take to charge a forklift battery?

- Part 4. Factors affecting forklift battery charging duration

- Part 5. The charging process for forklift batteries

- Part 6. Tips for efficient forklift battery charging

- Part 7. Safety considerations while charging forklift batteries

- Part 8. How does the size of the forklift battery impact charging time?

- Part 9. FAQs

When managing a fleet of forklifts, it is crucial to understand how long it takes to recharge their batteries. Why? Because downtime can significantly affect productivity. This article will explore the different types of forklift batteries, their charging times, and tips to ensure you get the most out of your battery life. Are you ready to dive into the world of forklift battery charging? Let’s get started!

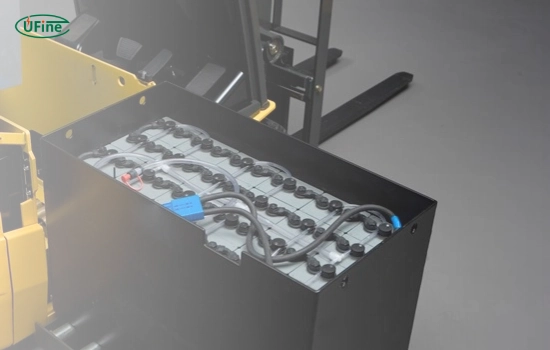

Part 1. What is a forklift battery?

A forklift battery is a powerhouse behind electric forklifts, providing the necessary energy to lift heavy loads and navigate around warehouses or job sites. The most common types of forklift batteries include lead-acid and lithium-ion batteries. But what sets them apart?

Lead-acid batteries are the traditional choice, known for their reliability and cost-effectiveness. Many industries widely use them and often favor them for their robustness. However, they require regular maintenance and have a shorter lifespan than lithium-ion batteries.

On the other hand, lithium-ion batteries are gaining popularity due to their higher efficiency, longer lifespan, and faster charging capabilities. These batteries can handle more charge cycles and typically have built-in management systems that enhance their performance. Understanding these differences is essential for making informed decisions about your forklift operations.

Part 2. Types of forklift batteries

When it comes to forklift batteries, there are primarily two types to consider:

- Lead-acid batteries are the most commonly used batteries in forklifts. They are relatively inexpensive and have a proven track record. However, they require regular maintenance and have a shorter lifespan than lithium-ion batteries, often lasting 3 to 5 years with proper care.

- Lithium-Ion Batteries: These batteries are more advanced and often have a higher initial cost. They require less maintenance and can charge much faster, making them ideal for operations that require frequent use. Lithium-ion batteries can last up to 10 years or more, making them a more cost-effective option in the long run.

Each type has pros and cons, and the choice often depends on the specific needs of your operation.

Part 3. How long does it take to charge a forklift battery?

Charging times for forklift batteries can vary significantly based on the type of battery and the charger used. Here’s a general overview:

- Lead-Acid Batteries: Typically, it takes about 8 hours to charge a conventional lead-acid forklift battery fully. After charging, it’s advisable to let the battery cool down for another 8 hours before use to ensure longevity. This extended cool-down period is crucial because it helps prevent overheating, which can damage the battery’s internal components.

- Lithium-Ion Batteries: Depending on the charger and battery specifications, these can reach a full charge in 1 to 3 hours. This rapid charging capability can significantly enhance operational efficiency, allowing more frequent use of the forklift throughout the day.

Understanding these charging times is crucial for effectively planning your forklift operations. By scheduling charging during off-peak hours or breaks, you can maximize the availability of your equipment.

Part 4. Factors affecting forklift battery charging duration

Several factors can influence how long it takes to recharge a forklift battery:

- Battery Type: As discussed, lead-acid batteries take longer to charge than lithium-ion batteries. The chemical processes in charging lead-acid batteries are slower, contributing to their longer charging times.

- Charger Type: The type of charger used can drastically affect charging times. Fast chargers can significantly reduce the time, while standard chargers may take longer. Smart chargers that adjust the charging rate based on the battery’s state can optimize the charging process.

- Battery Age and Condition: Older or poorly maintained batteries may take longer and hold a charge less efficiently. Regular maintenance checks can help identify issues before they impact performance.

- Temperature: Charging in extreme temperatures can affect battery performance and charging efficiency. Ideally, batteries should be charged in a controlled environment, as excessive heat and cold hinder the charging process.

Considering these factors, you can optimize your charging process and reduce downtime, ensuring your forklifts are always ready for operation.

Part 5. The charging process for forklift batteries

Charging a forklift battery involves several steps to ensure safety and efficiency:

- Establish a Safe Charging Station: Ensure the area is well-ventilated and free from flammable materials. Proper ventilation is essential, especially for lead-acid batteries, which can emit hydrogen gas during charging.

- Use the Correct Charger: Always use a charger compatible with your battery type to avoid damage. Mismatched chargers can lead to overcharging or undercharging, which can shorten battery life.

- Monitor the Charging Process: Monitor the battery during charging to prevent overheating or overcharging, which can lead to safety hazards. Many modern chargers have built-in monitoring systems that alert you to potential issues.

- Follow Manufacturer Guidelines: Adhering to the manufacturer’s instructions for charging can help prolong the battery’s lifespan and ensure safety. You should be aware of the specific requirements for each battery type.

By following these steps, you can ensure a safe and efficient charging process for your forklift batteries, minimizing risks and maximizing productivity.

Part 6. Tips for efficient forklift battery charging

To maximize the efficiency of your forklift battery charging process, consider the following tips:

- Charge During Breaks: If using lithium-ion batteries, charge during breaks or downtime to keep the battery topped up. This practice can significantly reduce the need for long charging sessions.

- Avoid Deep Discharges: Do not let your battery discharge completely before recharging, as this can shorten its lifespan. Regularly charging your battery before it reaches a low state can help maintain its health.

- Regular Maintenance: Keep your batteries clean and well-maintained. For lead-acid batteries, ensure adequate electrolyte levels and clean any corrosion from the terminals.

- Use Smart Chargers: Invest in smart chargers that adjust the charging rate based on the battery’s needs, optimizing the charging process. These chargers can also provide valuable data on battery health and charging cycles.

Implementing these tips can help you get the most out of your forklift batteries and reduce overall operational costs, increasing efficiency.

Part 7. Safety considerations while charging forklift batteries

Safety should always be a priority when charging forklift batteries. Here are some key considerations:

- Ventilation: Ensure the charging area is well-ventilated to disperse any gases released during charging, especially with lead-acid batteries. Hydrogen gas is highly flammable, making proper ventilation critical.

- Fire Safety: Keep fire extinguishers nearby and train all personnel in fire safety procedures. Regular fire drills can help ensure everyone knows how to respond in an emergency.

- Personal Protective Equipment (PPE): When handling batteries, workers should wear appropriate PPE, including gloves and safety goggles. This equipment can protect against acid spills and electrical hazards.

- Regular Inspections: Periodically inspect charging equipment and batteries for any signs of wear or damage. Early detection of issues can prevent accidents and prolong battery life.

By following these safety considerations, you can create a safer working environment during the charging process, protecting both your employees and your equipment.

Part 8. How does the size of the forklift battery impact charging time?

The size of a forklift battery plays a significant role in determining how long it takes to charge. Larger batteries typically have a higher capacity, which means they can store more energy but take longer to charge. Here are some key points to consider:

- Capacity Ratings: Forklift batteries are rated in amp-hours (Ah). A larger battery with a higher Ah rating will require more time to charge than a smaller one, assuming you use the same charger.

- Charging Equipment: The size of the battery may require specific charging equipment that can handle the increased load. An inadequate charger can lead to longer charging times and potential damage to the battery.

- Operational Needs: Planning for longer charging times is essential in operations where larger batteries are necessary for extended use. This may involve scheduling charging during off-peak hours or ensuring backup batteries are available.

Understanding how battery size impacts charging time can help you plan your operations more effectively, ensuring that your forklifts are always ready when needed.

Part 9. FAQs

-

How long does it usually take to charge a forklift battery?

Typically, it takes about 8 hours to charge a conventional lead-acid forklift battery fully. -

Can lithium-ion batteries be charged faster than lead acid?

Lithium-ion batteries can often reach full charge in as little as 1 to 3 hours. -

What are the signs that a forklift battery needs charging?

If the forklift struggles to lift loads or if warning lights indicate low battery, it is time to recharge. -

Is it safe to leave a forklift battery charging overnight?

Yes, but ensuring the charger has automatic shutoff features is essential to prevent overcharging. -

How can I extend the life of my forklift battery?

Follow proper charging protocols, avoid deep discharges, and maintain regular water levels in flooded lead-acid batteries.

Related Tags:

More Articles

Battery Load Test: A Comprehensive Guide

Step-by-step battery load test guide for car, solar & industrial use. Learn how to load test a battery, interpret voltage charts, and avoid common mistakes.

The Comprehensive Guide to Battery Balancing and Battery Balancer

Discover how battery balancers improve lithium battery performance, lifespan, and safety. Learn types, functions, and tips to choose the right balancer.

What Is the Best Voltage for a Chainsaw Battery?

Compare 12V-80V chainsaw batteries for light pruning, medium firewood, and professional cutting. See best battery chainsaw with runtime charts and safety tips.

Lithium VS. Alkaline Batteries: A Comprehensive Comparison

Lithium batteries last 3–7× longer than alkaline and perform better in cold weather. Compare lifespan, cost, safety, and best uses to choose the right battery.

Comparing Lithium-Sulfur and Lithium-Ion Batteries: Which is Right for You?

Compare lithium-sulfur (Li-S) and lithium-ion batteries on energy, lifespan, cost, safety, and applications. Best choice for drones, EVs, and electronics.