The demand for lithium-ion batteries is rising day-by-day with the growth of electric vehicles, energy storage systems, and small electric equipment. Many renowned manufacturers like Ufine Battery are working hard to fulfill energy needs. However, the cost of lithium batteries is 3 to 4 times higher than traditional lead acid batteries. What makes lithium-ion batteries more expensive? To know the real truth behind the costly price sticker of a lithium battery, we need to understand the factors contributing to its overall cost. Therefore, this article will cover manufacturing costs, including raw materials, labor, and production process costs.

Part 1. Lithium battery composition: material cost

A lithium battery is a composition of many chemical components that work together to store and release energy. Therefore, the cost of lithium batteries always relies on these components. Let’s see what is the principle work of these chemical components.

1. Lithium Battery Composition

Anode

Anode is a negative electrical rode that is usually made of graphite, which is carbon foam. During the charging process, lithium ions move into anode and store. So whenever the battery discharges these lithium ions, they move from anode to cathode and release charged energy.

Cathode

The cathode is a positive electrode made of different materials depending on the type of battery. The most common types are lithium cobalt (LiCoO2), lithium iron phosphate (LiFePO4), and lithium nickel manganese cobalt oxide (NMC). The choice of material determines the capacity voltage and the cost of lithium batteries.

Electrolyte

The electrolyte is like a facilitator medium that lets the lithium ions flow from the anode to the cathode during the charging and discharging process. It is a lithium salt chemically known as lithium hexafluorophosphate (LiPF6). The electrolyte is much cheaper and has little effect on rising lithium battery prices.

Separator

It is a thin layer of porous membrane that separates the anode and cathode portions. This is a protective layer to prevent short circuits. However, small passage holes let the ions pass between the anode and the cathode.

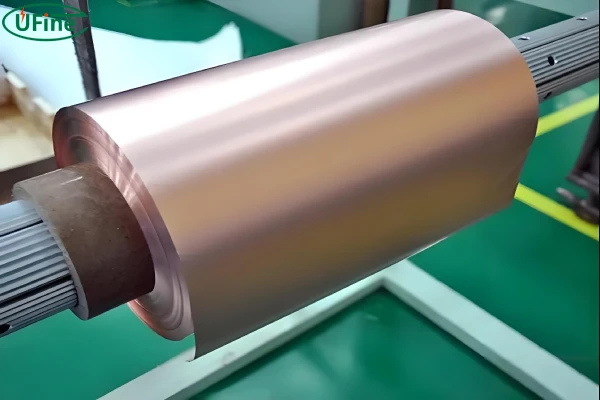

Current Collectors

A current collector is a thin foil of copper or aluminum connected with a cathode and anode. It collects current from lithium ions and channels it to the external circuit of the battery to power the device. It is also a factor in the cost of lithium batteries if current collectors are made of copper.

2. Lithium Battery Material Cost

The cost of lithium batteries is high due to its expensive material. Here is the detailed cost of each component for a better understanding.

Cathode Cost

The cathode is the most expensive material in lithium batteries. It is made of different materials depending on the battery type. The first type is lithium cobalt oxide (LCO), which can cost around $50 to $60 per kg. The second type is lithium iron phosphate (LFP), which costs around $15 to $20 per kg. The third type is lithium nickel manganese cobalt oxide (NMC), which costs $25 to $35 per kg. Due to variations in the price of each type of lithium material, the cost of lithium batteries varies from model to model.

Anode Cost

Anode is a form of carbon utilizing a grade graphite. So a high-quality graphite costs around $10 to $15 per kg. As technology advances, companies are working to utilize silicon graphite to extract more output from batteries. However, lithium batteries will be more expensive and increase the cost.

Electrolyte

The cost of electrolytes is between $5 to $10. Usually depends on purity and formulation required.

Separators Price

It is a thin layer between the cathode and anode and can cost up to $3 per square meter. A separator protects the battery from short circuits and allows ions to pass through.

Current Collectors

The current collectors can be made of aluminum or copper. The material difference also makes a difference in the cost of lithium batteries. An aluminum current collector’s price is $3 to $4 per kg, while copper has a double rate of $7 to $8 per kg.

Part 2. Lithium battery production process: production cost

1. Lithium Battery Production Process

A lithium battery production process follows some key steps until the final product is shaped. Each step contributes to the cost of lithium batteries. Here are some important steps in lithium battery production.

First, the electrode materials are prepared. This means mixing the active ingredients, like graphite and lithium compounds, and some binders and conductive additives to make a thick paste. This paste is then spread onto thin metal sheets using coating machines. The coated sheets are then dried and cut to size.

Next is about the cell assembly. The electrode layers are placed together with a separator in between. A separator prevents the short circuit. After that, the cell is filled with the liquid electrolyte solution and sealed completely. Special machines handle this delicate cell assembly process.

In the final step, they test each cell before assembling it into a large battery pack. This involves connecting multiple cells and integrating the battery management system. Automated assembly lines and testing equipment are used for this stage.

2. Required Equipment Estimated Cost

- After learning about the process of battery production and the reason for the high cost of lithium batteries, you should know each piece of equipment and its cost for a better understanding.

- Mixing Equipment: It mixes the active materials with binders and solvents to create a slurry for the electrodes. The estimated cost of these mixers is around $1 million to $2 million.

- Coating Machines: Coating machines are necessary to apply the slurry onto current collectors, costing you around $2 million to $3 million.

- Drying Ovens: To remove the solvent from the coated electrodes, dying ovens are important equipment that can cost about $500,000 to $1 million.

- Calendering Machines: Compressing the coated electrodes to achieve the desired thickness and density requires spending around $1 million to $2 million on calendering machines.

- Slitting Machines: It cuts the electrodes into the required sizes for assembly, which cost $300,000 to $500,000.

- Electrolyte Filling Equipment: It fills the electrolyte to the cells, costing $500,000 to $1 million.

- Formation and Aging Equipment: For charging and discharging the cells from the solid electrolyte interphase (SEI) layer and ensuring performance consistency, formation and aging equipment need to cost around $2 million to $3 million.

| Equipment | Estimated Cost |

|---|---|

| Mixing Equipment | $1 million to $2 million |

| Coating Machines | $2 million to $3 million |

| Drying Ovens | $500,000 to $1 million |

| Calendering Machines | $1 million to $2 million |

| Slitting Machines | $300,000 to $500,000 |

| Electrolyte Filling Equipment | $500,000 to $1 million |

| Formation and Aging Equipment | $2 million to $3 million |

3. Production Cost

Production cost is another factor contributing to the rising cost of lithium batteries. It has a direct impact on the lithium battery price. However, the production cost can vary from time to time. In 2024, when the lithium battery price is rising, the estimated production cost per kWh is as follows.

4. Raw materials, including lithium cost as discussed in Part 1, $50 to $100

5. Labor can vary from region to region and can cost around $5 to $10

6. Energy costs, including electricity, water, and gas, are $5 to $10

7. Maintenance and operational costs are around $5 to $10

8. Depreciation of Equipment $10 to $20

9. Total: $75 to $150 per kWh

Part 3. What affects the cost of lithium batteries?

Many factors affect the cost of lithium batteries. Some of the important elements are as follows.

- Raw Material Prices: A lithium battery is a combination of many materials. The primary material, lithium cost, is high compared to other traditional lead acid batteries. Graphite, cobalt, electrolytes, separators, etc., contribute to lithium batteries’ estimated cost.

- Economies of Scale: The level of production also affects lithium battery prices. If there is a large-scale production, the cost per unit decreases, while small industry rates are high in production.

- Regulatory Policies; Regulatory policies like taxes, rules, and regulations are also a determining factor in the cost of lithium batteries.

- Market Demand; Demand and supply also affect the lithium battery price. If there is a high demand, the price will rise, and in case of low demand, the lithium battery price.

- Innovation in Recycling; An innovative way of recycling can cut and lower the cost of raw materials. So, the per kWh cost of lithium batteries decreases, which is beneficial both for companies and users.

- Labor Costs: Labor cost is another factor affecting lithium battery prices. The cost of labor can vary from one region to another. However, an automotive machine can lower the cost per watt in production.

Part 4. Final thoughts

We know the demand for lithium batteries is increasing daily, and many manufacturers are trying to accommodate these needs. Ufine Battery is already a well-known Chinese lithium battery manufacturer offering everyone versatility and customized solutions. It works with a full-process production line and battery manufacturing equipment, with a daily output of 100,000+ units. Therefore, Ufine Battery is an ideal solution for consumers and industries working on a large scale.

Related Tags:

More Articles

Paper Battery vs. Flexible Battery: What’s the Difference and Which Is Better?

Paper vs. flexible batteries: learn the key differences, benefits, and which power source fits best for wearables, sensors, and smart tech.

What to Know Before Buying a Tiny LiPo Battery for Your Project

Tiny LiPo batteries are powerful and compact. Learn how to choose the right one for your project with specs, safety, and charging tips.

Bloated LiPo Battery: Will It Explode?

Will a bloated LiPo battery explode? Discover the causes, risks, safety steps, and expert tips to avoid disaster and protect your gear. Must-read safety guide!

12V 100Ah Lithium Ion Battery Price: Full Guide

Learn about 12V 100Ah lithium-ion battery price, from cost ranges to best brands, hidden fees, and how to get the best deal. A must-read for smart buyers!

Resistance and Conductivity: What It Means for Your Lithium Batteries

Resistance and conductivity impact lithium battery performance, lifespan, and safety—learn how they work and why they matter.