- Part 1. Learn LFP material

- Part 2. How does LFP cathode material affect battery performance?

- Part 3. where do LFP battery raw materials come from?

- Part 4. LFP cathode material distribution globally

- Part 5. LFP cathode material advantages

- Part 6. Preparation process of LFP cathode material

- Part 7. The production process of lithium carbonate

- Part 8. Summary

- Part 9. FAQs

Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing cost, good cycle performance, and environmental friendliness, it has become a hot topic in the current research of cathode materials for power batteries.

In the production process of LFP batteries, the anode material is one of the critical factors of battery performance. Among them, lithium carbonate, phosphoric acid, and iron are the three most vital raw materials for preparing LFP battery anode materials. In this paper, the performance of lithium iron phosphate and the production process of the three raw materials will be introduced to introduce their role and importance in preparing LFP battery cathode materials.

Part 1. Learn LFP material

The LFP cathode is a key part of the Lithium Iron Phosphate (LFP) battery, and it plays an essential role in the energy storage and release processes. Composed of lithium iron phosphate, the LFP cathode is what allows the battery to charge and discharge safely while offering long life cycles.

LFP cathode material differs from the more commonly known lithium cobalt oxide (LCO) used in many other batteries, including some electric vehicle applications. By replacing cobalt with iron, LFP batteries offer a cheaper, more abundant, and environmentally friendly alternative. LFP cathodes are known for their excellent thermal stability and chemical resilience, which significantly enhances the safety profile of the batteries.

The positive electrode material of LFP battery is mainly lithium iron phosphate (LiFePO4). The positive electrode material of this battery is composed of several key components, including:

- Phosphoric acid: The chemical formula is H3PO4, which plays the role of providing phosphorus ions (PO43-) in the production process of lithium iron phosphate.

- Lithium hydroxide: The chemical formula is LiOH, which is another main raw material for the preparation of lithium iron phosphate and provides lithium ions (Li+).

- Iron salt: Such as FeSO4, FeCl3, etc., used to provide iron ions (Fe3+), reacting with phosphoric acid and lithium hydroxide to form lithium iron phosphate.

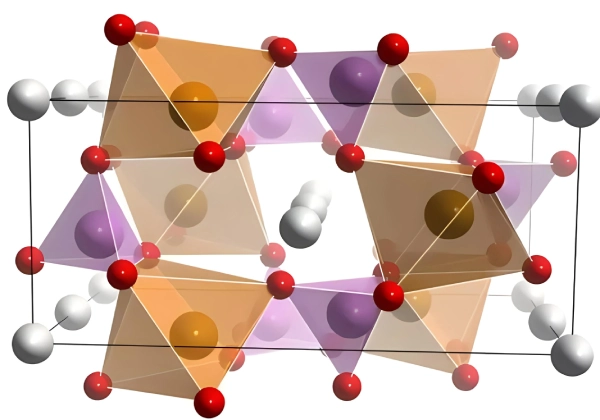

Lithium iron phosphate has an ordered olivine structure. Lithium iron phosphate chemical molecular formula: LiMPO4, in which the lithium is a positive valence: the center of the metal iron is positive bivalent; phosphate for the negative three valences, commonly used as lithium battery cathode materials.

Part 2. How does LFP cathode material affect battery performance?

The impact of lithium iron phosphate positive electrode material on battery performance is mainly reflected in cycle life, energy density, power density and low temperature characteristics.

1. Cycle life

The stability and loss rate of positive electrode materials directly affect the cycle life of lithium batteries. During the charging and discharging process, the loss of active substances in positive electrode materials and the destruction of material structure will lead to the attenuation of battery performance. In addition, impurities in positive electrode materials, such as elemental iron and trivalent iron, may react adversely with the electrolyte, causing micro-short circuits inside the battery, thereby affecting the cycle life.

2. Energy density

The theoretical energy density of positive electrode materials determines the upper limit of the energy density of lithium battery cells. At the same time, the dosage design of positive electrode materials and the tap density during the processing and manufacturing process will also affect the energy density of the finished battery cells.

3. Power density

The type and characteristics of positive electrode materials determine the range of charging and discharging power of lithium-ion batteries. Factors such as the stability of the material’s crystal structure, particle size, doping atoms, carbon coating process, and preparation method will affect the positive electrode material’s ability to accommodate lithium ions and the patency of the embedding and de-embedding channels, thereby affecting the power density of lithium-ion batteries.

4. Low-temperature characteristics

Under low-temperature conditions, the performance of lithium iron phosphate batteries is extremely poor, and even nano-sizing and carbon coating cannot completely improve it. This is because the positive electrode material itself has weak electronic conductivity and is prone to polarization, which reduces the battery volume.

At the same time, the negative electrode also has a great impact on low-temperature charging, which will affect the safety of the battery. In addition, the viscosity of the electrolyte increases under low-temperature conditions, which increases the characteristic impedance of lithium-ion battery transfer.

Part 3. where do LFP battery raw materials come from?

LFP batteries are composed of several critical raw materials, with the LFP cathode being one of the most important. The primary raw materials involved in the production of LFP batteries are:

- Iron (Fe): The base material for the cathode, which is abundant and affordable.

- Phosphate (PO4): A naturally occurring mineral that stabilizes the cathode material.

- Lithium (Li): A key element for the overall battery function, providing the necessary ions for energy storage and release.

Other materials used in the manufacturing of LFP batteries include carbon and aluminum, which are used for the anode and the battery casing, respectively. The availability of these raw materials is crucial for meeting the growing demand for LFP battery technology.

Part 4. LFP cathode material distribution globally

One of the most notable trends in the global battery market is the increasing production and use of LFP cathodes. Unlike cobalt and nickel, which are concentrated in specific geographic regions, iron, the primary material used in LFP cathodes, is more evenly distributed worldwide. As a result, LFP battery raw materials are less dependent on specific countries, giving LFP batteries a more secure and sustainable future.

Global Distribution of LFP Cathode Materials

- China: The largest producer of iron and the leader in LFP battery production. Chinese manufacturers dominate the LFP market, supplying both the raw materials and finished batteries.

- Brazil and Australia: Key suppliers of iron ore, with these countries exporting large quantities of iron to meet the growing global demand for LFP materials.

- United States and Europe: While they have limited domestic production of LFP cathodes, both regions are investing heavily in battery manufacturing and raw material supply chains to reduce dependency on foreign imports.

This global distribution of LFP materials ensures a more diversified and resilient supply chain, which is crucial as the demand for sustainable battery solutions continues to grow.

Part 5. LFP cathode material advantages

Compared with other lithium battery cathode materials, the olivine structure of lithium iron phosphate has the advantages of safety, environmental protection, cheap, long cycle life, and good high-temperature performance. Therefore, it is one of the most potential cathode materials for lithium-ion batteries.

1. Safety

Lithium iron phosphate crystals have a solid P-O bond, which is difficult to decompose. The structure will not collapse and heat in lithium-ion battery overcharge and high temperatures or generate substantial oxides. Therefore, even if the battery is overcharged, it is also relatively safe.

2. Long cycle life

The cycle life of the lead-acid battery is about 300 times. The service life is between 1~1.5 years. The cycle life of the LiFePO4 battery is more than 2000 times. Theoretically, the service life can reach 7~8 years.

3. High temperature resistance

LiFePO4 battery can reach 350℃-500℃. At the same time, lithium manganese and cobalt are only about 200 ℃.

4. Environmentally friendly

LiFePO4 battery is generally considered free of heavy and rare metals, non-toxic, non-polluting, and green.

Lithium iron phosphate’s charging and discharging mechanism as cathode material differsnt from other traditional materials. The electrochemical reaction of lithium iron phosphate is the two phases of iron phosphate, and the charging and discharging reactions are as follows.

Charge reaction.

LiFePO4 -xLi+ -xe-→xFePO4 +(1-x)LiFePO4

Discharge reaction.

FePO4+xLi+ +xe-→xLiFePO4+(1-x)FePO4

Li+ detaches from LiFePO4, on charging, and Fe2+ loses an electron to become Fe3+.

When discharged, Li+ is embedded in iron phosphate to become LiFePO4.

The Li+ change occurs at the LiFePO4/FePO4 interface. Therefore, its charge/discharge curve is very flat. The potential is also more stable. Suitable for electrode materials.

5. Cost advantage

LFP positive electrode raw materials are widely available and cheap. This makes lithium iron phosphate batteries cost competitive, especially in the electric vehicle industry, where prices have dropped to a low level. Compared with other types of lithium-ion batteries, it has a cost advantage.

Part 6. Preparation process of LFP cathode material

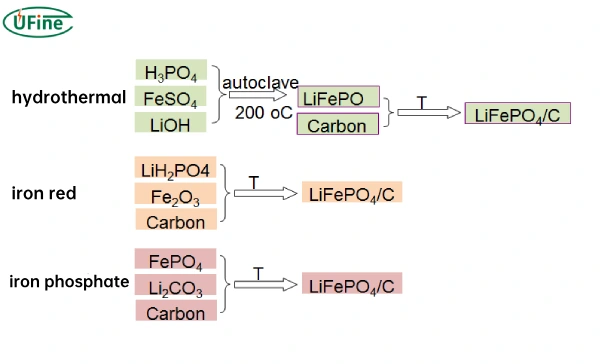

The common preparation processes of LFP positive electrode materials include solid phase synthesis, liquid phase synthesis, spark plasma sintering technology, spray thermal decomposition technology and pulsed laser deposition.

Common routes include hydrothermal, iron red and iron phosphate.

The iron phosphate process is favored by many material manufacturers because of its advantages such as less raw materials, no need to use solvents, water system mixing, no ammonia emission and low process cost. The main production processes include mixing, spray drying, sintering, crushing, mixing, baking and packaging.

Part 7. The production process of lithium carbonate

1. Lithium carbonate

Lithium carbonate is one of the important raw materials for the preparation of lithium iron phosphate anode materials. The production process of lithium carbonate mainly includes the steps of ore dressing, leaching and extraction, carbonate precipitation and lithium carbonate purification.

First, lithium salt is extracted from lithium ore. Then, the lithium salt is converted into lithium carbonate by chemical reaction. Finally, the purification process is carried out to obtain high-purity lithium carbonate.

The purity and crystallinity of lithium carbonate have an important impact on the performance of anode materials. Therefore, in the production process, we need to strictly control the process parameters to ensure that the quality of lithium carbonate meets the requirements.

2. Phosphoric acid

Phosphoric acid is another important raw material for the preparation of LiFePO4 cathode materials. The production process of phosphoric acid mainly includes the beneficiation of phosphate ore, leaching and extraction, phosphate precipitation, and phosphoric acid purification steps.

First, the phosphorus salt is extracted from the phosphate ore. Then, the phosphorus salt is converted into phosphoric acid by chemical reaction. Finally, the purification process is carried out to obtain high purity phosphoric acid.

The purity and crystallinity of phosphoric acid also have an important impact on the performance of cathode materials. Therefore, in the production process, it is also necessary to strictly control the process parameters to ensure that the quality of phosphoric acid meets the requirements.

3. Iron

Iron is the third important raw material for the preparation of lithium iron phosphate anode materials. The production process of iron mainly includes steps such as ore dressing, leaching and extraction, oxidation-reduction, and iron powder preparation.

First, iron salts are extracted from iron ore. Then, the iron salt is converted into iron powder by a redox reaction. Finally, the refining process is carried out to obtain high-purity iron powder.

The purity and particle size of iron powder also have an important impact on the performance of cathode materials. Therefore, it is also necessary to strictly control the process parameters in the production process to ensure that the quality of iron powder meets the requirements.

Part 8. Summary

In summary, lithium carbonate, phosphoric acid, and iron are three critical raw materials for preparing LFP battery cathode materials. Their production process directly affects the performance and quality of anode materials. In the actual production, it is necessary to strictly control the process parameters to ensure that the quality of raw materials meets the requirements to ensure the performance and stability of the final cathode material. At the same time, continuously optimizing the raw material production process and improving the purity and crystallinity of the raw material will help enhance the cathode material’s performance. This will help to improve the performance, reduce the cost of anode materials, and promote the development and progress of the lithium battery industry.

Part 9. FAQs

-

How to charge the LFP battery?

Charge an LFP battery using a specifically designed charger, following the manufacturer’s instructions for proper voltage, current, and charging duration. -

What is the voltage of the LFP battery?

The voltage of an LFP battery is typically around 3.2 to 3.3 volts per battery, providing a total voltage based on the number of cells connected in series. -

Will the LFP battery explode?

LFP batteries have a lower risk of explosion than other lithium-ion chemistries due to their more stable chemistry and higher thermal stability. -

What are the disadvantages of LFP batteries?

Disadvantages of LFP batteries include lower energy density compared to other lithium-ion chemistries, higher cost, and a slightly lower specific power. -

How many years does an LFP battery last?

The lifespan of an LFP battery can vary depending on factors such as usage patterns, charging methods, and operating conditions. It can typically last for several years before experiencing significant capacity loss.

Related Tags:

More Articles

What is the Difference Between Silver Zinc Battery vs. Lithium-ion Rechargeable?

Compare silver zinc and lithium-ion rechargeable batteries: energy density, cycle life, safety, cost, and uses in drones, medical devices, EVs, and electronics.

What are Watts and Watt Hours in Battery?

Understand watt vs watt-hour in batteries: key differences, how to calculate capacity, and why they matter. Includes free comparison table.

Best 10 Blood Pressure Monitor Battery Review: Finding the Most Reliable

Are you looking for a reliable Blood Pressure Monitor battery? Here is a complete guide with the top 10 best blood pressure monitor batteries.

Bluetooth Headphone Battery Guide: All You Need to Know

Maximize headphone battery life with expert tips! Learn how to charge, check, troubleshoot, and choose the best bluetooth headphone battery in 2025.

LiFePO4 Battery VS. Lithium-ion Polymer Battery: Which One Is Best?

Comprehensive comparison of LiFePO4 vs Lithium Ion Polymer batteries: energy density, safety, lifespan, cost. Find out which battery suits your needs in 2025.