- Part 1. What is a lithium-air battery?

- Part 2. What is a lithium-sulfur battery?

- Part 3. Lithium air vs. lithium sulfur battery key differences

- Part 4. Advantages of lithium-air and lithium-sulfur batteries

- Part 5. Disadvantages of lithium-air and lithium-sulfur batteries

- Part 6. Comparison table: lithium-air vs. lithium-sulfur batteries

- Part 7. Applications of lithium-air and lithium-sulfur batteries

- Part 8. FAQs

Lithium-based batteries are leading the way in energy storage for electric vehicles and renewable energy systems. Among these, lithium-air and lithium-sulfur batteries stand out. Both use lithium but work in different ways. Each type has its own benefits and challenges. This article will compare lithium-air and lithium-sulfur batteries, looking at how they work, their pros and cons, and their uses.

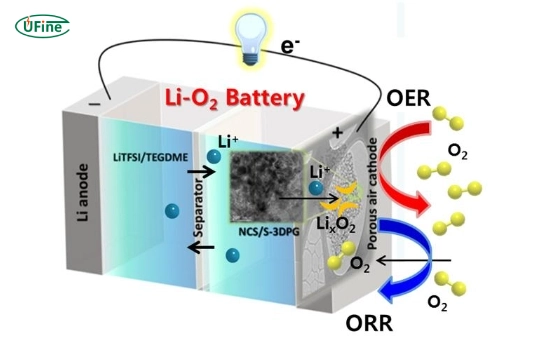

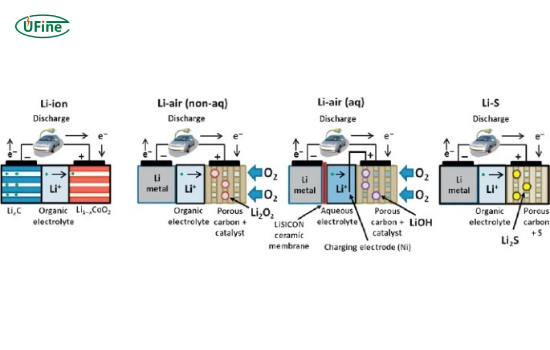

Part 1. What is a lithium-air battery?

Lithium-air batteries (Li-air) are a new type of rechargeable battery. They use lithium for the anode and oxygen from the air for the cathode. This design has a theoretical energy density of 5,200 Wh/kg, much higher than the 150-250 Wh/kg of typical lithium-ion batteries.

In a lithium-air battery, lithium ions move from the anode to the cathode during discharge. There, they react with oxygen to create lithium oxides, like lithium peroxide and lithium oxide. While they have high theoretical energy, real-world use is limited by issues like short cycle life and performance decline.

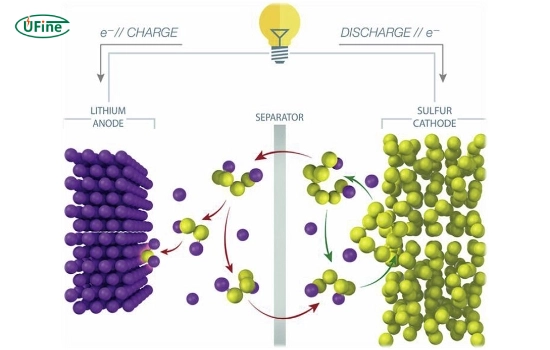

Part 2. What is a lithium-sulfur battery?

Lithium Sulfur Batteries (Li-S) represent another significant advancement in battery technology. These batteries utilize lithium as the anode and sulfur as the cathode, achieving an energy density of around 550 Wh/kg. This makes them lighter and cheaper than lithium-ion batteries.

The discharge process in lithium-sulfur batteries involves the conversion of sulfur into lithium sulfide (Li2S), which is a more straightforward reaction than that of lithium-air batteries. This simplicity improves cycle stability and efficiency, making Li-S batteries a promising alternative for various applications.

Part 3. Lithium air vs. lithium sulfur battery key differences

Energy Density

Energy density is a key difference between Li-air and Li-S batteries. Lithium-air batteries have a high theoretical energy density, but it’s hard to achieve this in real use. The highest recorded practical energy density for lithium-air batteries is about 362 Wh/kg, which is lower than their theoretical value due to engineering issues.

In contrast, lithium-sulfur batteries offer a more stable energy density in real-world use. This makes them more practical for energy storage and electric vehicles.

Performance and Lifespan

Lithium-air batteries generally have a shorter lifespan compared to lithium-sulfur batteries. They often degrade after about 50 cycles due to internal reactions that reduce efficiency and stability.

In contrast, lithium-sulfur batteries can last over 1,500 cycles thanks to improvements in materials and designs. However, they still face issues like the polysulfide shuttle effect, which causes capacity loss and operational problems. Researchers are working to improve these aspects for better performance.

Part 4. Advantages of lithium-air and lithium-sulfur batteries

Lithium-Air Batteries

The potential benefits of lithium-air batteries include:

- Significantly higher specific energy potential under optimal conditions.

- They are of lower weight, making them attractive for use in electric vehicles and aerospace applications.

- The ability to utilize ambient air reduces the weight attributed to stored oxidizers.

Lithium Sulfur Batteries

On the other hand, lithium-sulfur batteries offer several critical advantages:

- Higher energy density in practical applications, consistently outperforming lithium-ion batteries.

- Better cycle stability and longevity, making them more reliable for commercial and consumer applications.

- Lower resource costs associated with sulfur compared to materials commonly used in lithium-ion batteries, such as cobalt.

Part 5. Disadvantages of lithium-air and lithium-sulfur batteries

Lithium-Air Batteries

The potential drawbacks of lithium-air batteries include:

- They exhibit low efficiency due to significant energy losses during electrochemical reactions.

- The cycle life of lithium-air batteries is relatively short, as byproducts degrade the battery components.

- Managing oxygen intake and moisture from the air presents technical challenges in battery design.

- The charge and discharge rates are slower, limiting their use in applications requiring quick energy delivery.

Lithium-Sulfur Batteries

Lithium-sulfur batteries also face several challenges:

- The polysulfide shuttle effect causes capacity loss and reduces battery efficiency over time.

- Lithium-sulfur batteries generally have a shorter cycle life compared to lithium-ion batteries.

- The volume expansion of sulfur during lithiation can lead to mechanical stress and internal damage.

- Sulfur’s low electrical conductivity necessitates using conductive additives, which can reduce energy density.

Part 6. Comparison table: lithium-air vs. lithium-sulfur batteries

To provide a clearer understanding of the differences between lithium-air and lithium-sulfur batteries, here’s a concise comparison table:

| Feature | Lithium Air Battery | Lithium Sulfur Battery |

|---|---|---|

| Energy Density | Theoretical: 5,200 Wh/kg | Practical: ~550 Wh/kg |

| Cycle Life | ~50 cycles | >1,500 cycles |

| Weight | Lightweight due to air utilization | Lightweight due to sulfur use |

| Cost | Potentially high due to complexity | Generally lower due to sulfur |

| Efficiency | Lower due to reaction complexity | Higher efficiency in energy conversion |

| Environmental Impact | Uses ambient air, reducing oxidizer weight | Sulfur is abundant and less toxic |

| Commercial Availability | Still in the research phase | Already in commercial applications |

Part 7. Applications of lithium-air and lithium-sulfur batteries

Lithium-Air Batteries

Lithium-air batteries are still in the research phase. Designers see them as useful for applications where weight and energy density are important, like electric vehicles, aerospace, and portable electronics. Their ability to use oxygen from the air could reduce weight significantly, which is key for efficiency in demanding environments.

Lithium Sulfur Batteries

Lithium-sulfur batteries are already used in several commercial applications, including electric vehicles and renewable energy storage. They offer significant weight savings and better energy density. This makes them suitable for future uses, like smart grids and powering electronic devices where long battery life is important.

Part 8. FAQs

-

What is the lifespan of lithium-air batteries?

Lithium-air batteries typically have a limited lifespan, often degrading significantly after about 50 cycles. -

How does the energy density of lithium-sulfur batteries compare to lithium-ion batteries?

Lithium-sulfur batteries offer higher energy densities, generally up to 550 Wh/kg, compared to lithium-ion batteries, which range from 150 to 260 Wh/kg. -

What are the main challenges facing lithium-air batteries?

The main challenges include low cycle life and a complex discharge process, which limits their performance in practical applications. -

Are lithium-sulfur batteries commercially available?

Some applications, primarily in electric vehicles and renewable energy systems, already utilize lithium-sulfur batteries. -

What future developments are expected in lithium battery technology?

Future developments will likely focus on improving energy density and lifespan and reducing costs, making these technologies more viable for widespread use.

Related Tags:

More Articles

How Long Do Rechargeable AA Batteries Last?

How long do rechargeable AA batteries last? Compare NiMH and lithium AA lifespan, recharge cycles, key factors, and performance vs alkaline batteries.

12V STD vs 12V AGM: Meaning, Differences, and Which Is Better

Understand what STD and AGM batteries mean, their key differences, and which 12V battery fits your needs best in 2026.

Battery Reconditioning Explained: A Comprehensive Guide

Learn what battery reconditioning is, how it works, how long it takes, and when reconditioning chargers are used for lead-acid and lithium-ion batteries.

Recommended 10 Best Batteries For Smoke Detectors

Compare the best batteries for smoke detectors in 2026. See which 9V lithium and alkaline batteries last longest and perform best in smoke alarms.

Triple A Battery Voltage: Everything You Need to Know

How many volts is a AAA battery? See a clear AAA battery voltage chart, compare alkaline, lithium and NiMH cells, and learn how voltage affects device use.