What is a Battery Voltage Chart? A battery voltage chart is a critical tool for understanding how different lithium-ion batteries perform under specific conditions. It displays voltage parameters like rated voltage (3.2V-4.2V), open-circuit voltage, and termination voltage, helping users select the right battery for devices like smartphones, EVs, or solar storage systems.

A battery is a device that converts chemical energy into electrical energy, which is widely used in various fields, such as electronic equipment, transport, energy reserves, and so on. Different battery materials determine the performance characteristics of the battery, and one important parameter is the battery voltage. We will take you through the lithium-ion battery voltage chart.

Part 1. Lithium-ion battery voltage chart and definitions

The lithium-ion battery voltage chart is a comprehensive guide to understanding the potential difference between the battery’s two poles. Key voltage parameters within this chart include rated voltage, open circuit voltage, working voltage, and termination voltage.

| Voltage Type | Description | Example (NCM) | Example (LFP) |

| Rated Voltage | Nominal design voltage under normal use | 3.7V | 3.2V |

| Open Circuit Voltage | Voltage when no load is applied | 3.3V | 3.0V |

| Termination Voltage | Minimum safe discharge voltage | 2.5V | 2.5V |

Rated voltage

The rated voltage is the nominal value and belongs to the theoretical voltage on behalf of the design voltage. The theoretical voltage is the maximum limit of the battery voltage, and the theoretical voltage of the battery is different for different materials.

Open circuit voltage

The open circuit voltage refers to the open circuit voltage is the potential difference between the positive and negative terminals of the battery when there is no current passing through the battery, that is, the voltage between the positive and negative terminals when the battery is not working. For example, the open-circuit voltage of lithium-ion batteries is generally around 3V, and sodium-ion batteries will be below 3V.

Working voltage

The working voltage refers to the voltage at both ends of the battery when it is working, that is, the actual voltage of the battery. Generally, the actual voltage is less than the open-circuit voltage because the battery needs to overcome the battery’s polarization and internal resistance when working.

Termination voltage

The termination voltage refers to the maximum charging and discharging voltage of the battery in the process of charging or discharging. Suppose the voltage is lower than the discharge termination voltage after the battery discharges. In that case, the voltage at both ends of the battery will drop rapidly, forming a deep discharge, so that the plate’s formation on the product’s formation in the standard charging is not easy to recover, thus affecting the life of the battery.

Part 2. Lithium-ion battery voltage chart for different materials

Different battery materials have different battery voltages caused by the differences in their chemical reaction processes and electron transfer mechanisms. The following are several common battery materials and their corresponding battery voltages:

|

Battery Type |

Positive Electrode Material |

Negative Electrode Material |

Voltage Range |

Advantages |

|

Ternary Material Batteries |

Lithium-nickel-cobalt-manganese oxide (LiNiCoMnO2) |

Graphite or other carbon materials |

2.5V to 4.2V |

Efficient charge transfer, electrical energy generation during charging and discharging, versatile applications. |

|

Lithium-Iron Phosphate Battery |

Lithium iron phosphate (LiFePO4) |

Carbon |

3.2V (rated), 3.6V to 3.65V (charging cut-off) |

High operating voltage, high energy density, long cycle life, good safety performance, low self-discharge rate, no memory effect. |

|

Lithium Cobaltate Battery |

Lithium cobalt oxide (LiCoO2) |

Graphite or other carbon materials |

3.6V to 4.2V |

Suitable for various applications, moderate voltage range. |

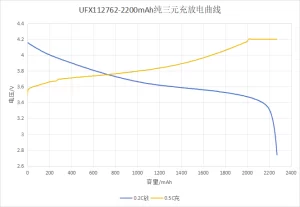

Ternary material batteries

The positive electrode material of ternary material batteries is lithium-nickel-cobalt-manganese oxide (LiNiCoMnO2), composed of lithium, nickel, cobalt, and manganese. In contrast, the harmful electrode material comprises graphite or other carbon materials. Lithium ions move back and forth between the positive and negative electrodes during the charging and discharging process, generating electrical energy by charge transfer through the electrolyte medium. The voltage range of batteries made of ternary materials is between 2.5V and 4.2V.

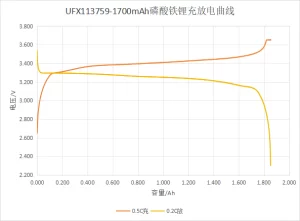

Lithium-iron phosphate battery

Lithium iron phosphate battery is a kind of lithium-ion battery using lithium iron phosphate (LiFePO4) as the cathode material and carbon as the anode material, with a single rated voltage of 3.2 V and a charging cut-off voltage of 3.6 V to 3.65 V. Lithium iron phosphate battery has the advantages of high operating voltage, high energy density, long cycle life, good safety performance, low self-discharge rate, and no memory effect.

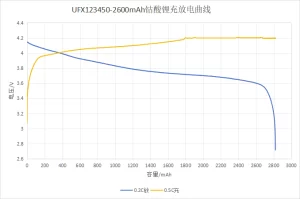

Lithium cobaltate battery

The buoyant material of a lithium cobaltate battery is lithium cobalt oxide (LiCoO2), which is composed of lithium, cobalt, and oxygen. In contrast, the harmful material is graphite or other carbon materials. Its battery voltage is usually 3.6 volts (V) to 4.2 volts (V).

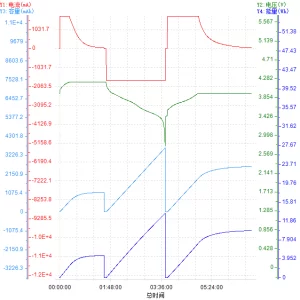

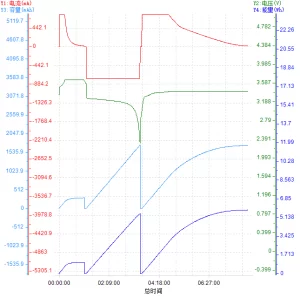

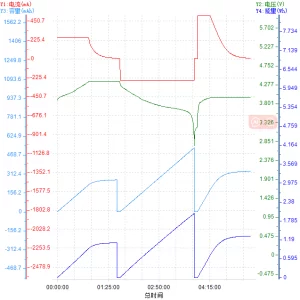

Lithium-ion battery charge and discharge curve:

1)NCM 2)LFP

3)LiCOO2

The relationship between battery voltage and capacity, the corresponding battery state:

1)NCM 804585 3.7 V 3500mAh 2)LFP 904062 3.2 V 1500mAh

3)LiCOO2 782525 4.2 V 510mAh

Lithium Battery Voltage vs. Capacity: Key Insights

The voltage-capacity relationship determines a battery’s usable energy. For example:

- NCM 804585 3.7V 3500mAh: Voltage drops from 4.2V (100% SOC) to 3.0V (0% SOC).

- LFP 904062 3.2V 1500mAh: Stable voltage plateau (3.2V-3.0V) ensures 80% capacity even at 20% SOC.

Part 4. Why do you need to know about lithium-ion battery voltage?

Diverse material impacts

Lithium batteries vary in their voltage ranges based on the materials used in their construction. Selecting the appropriate battery is pivotal as it directly influences equipment performance and safety. The nuanced differences in voltage among lithium battery variants necessitate precise selection to guarantee optimal functioning and mitigate potential risks associated with incompatible voltages.

Performance alignment

Battery voltage serves as a pivotal metric defining the energy output capacity of the battery. Varied applications require specific voltage ranges to operate effectively. High-powered devices demand batteries with a higher voltage for sufficient power output. In contrast, low-powered devices can function optimally with lower-voltage batteries. A comprehensive understanding of battery voltage ranges facilitates the meticulous selection of batteries, ensuring seamless device operation and peak performance across diverse usage scenarios.

Compatibility and integration

Understanding lithium-ion battery voltage is crucial for ensuring compatibility and seamless integration within devices or systems. Different devices are designed to operate within specific voltage ranges, and selecting the appropriate battery voltage ensures optimal performance and safety. Using a battery with an incompatible voltage could lead to malfunction or potential damage to the equipment.

Safety considerations

Voltage plays a significant role in the safety of lithium-ion batteries. In extreme cases, overvoltage or undervoltage scenarios can cause issues like overheating, leakage, or even explosion. Being aware of the correct voltage range helps prevent these hazardous situations, ensuring battery-powered devices’ longevity and safe operation.

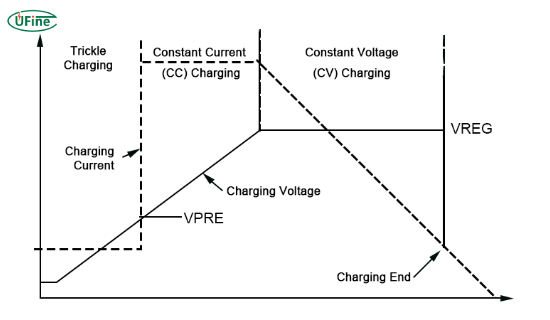

Charging and discharging efficiency

It is understanding the voltage range of lithium-ion batteries aids in efficient charging and discharging processes. It helps in determining the right charging protocols and discharge rates, optimizing the battery’s performance, and prolonging its lifespan. Charging a battery with an inappropriate voltage could reduce efficiency or damage to the battery cells.

Regulatory compliance

Voltage specifications often align with industry standards and regulations. Ensuring that the battery voltage meets these standards is essential for compliance purposes, especially in regulated sectors like medical devices or aviation, where adherence to specific voltage ranges is mandatory for safety and quality standards.

Part 5. FAQs about lithium battery voltage chart

What is the voltage of a fully charged lithium-ion battery?

A fully charged NCM battery reaches 4.2V, while LFP batteries peak at 3.65V. Always refer to the battery voltage chart for exact values.

How to read a lithium battery voltage chart?

Check the rated voltage (e.g., 3.7V for NCM), open circuit voltage (resting state), and termination voltage (minimum safe level). Compare curves for different materials.

Why do LFP batteries have lower voltage?

LFP’s stable iron-phosphate chemistry provides 3.2V nominal voltage vs NCM’s 3.7V, but offers longer cycle life and thermal safety.

Part 6. Conclusion

In short, understanding the voltage range of batteries is crucial to properly selecting and using lithium batteries. As a company specializing in producing high-quality lithium batteries, Ufine is committed to providing reliable battery products and LFP batteries that meet the needs of our customers. Our products have stability, reliability, and high performance to meet the needs of various application scenarios. By choosing Ufine’s lithium batteries, you can rest assured that you can use them and get a quality electrical energy supply.

Related Tags:

More Articles

How to Choose the Best Floor Scrubber Battery for Commercial Cleaning?

Selecting the ideal floor scrubber battery ensures a long runtime, rapid charging, and minimal maintenance for efficient commercial cleaning operations.

Battery for Blower vs Battery for Leaf Vacuum: Which One Should You Choose?

Battery for blower vs leaf vacuum—learn the key differences in power, fit, and runtime to choose the right battery for your outdoor tool needs.

How to Choose the Right Battery for Blower?

Choosing the right blower battery? Consider voltage, capacity, chemistry & usage. This guide helps match the best battery for peak performance.

How to Choose the Best Insulated Battery Box for Lithium Batteries?

Choosing the Best Insulated Battery Box for Lithium Batteries? Discover key factors such as size, material, and safety for optimal protection and performance.

7 Critical Elements on a Lithium Battery Shipping Label

What must be on a lithium battery shipping label? Learn 7 key elements to ensure safety, legal compliance, and correct handling across all transport modes.