Selecting the right material is critical when it comes to battery enclosures for lithium battery applications. The enclosure protects the battery and plays a vital role in its performance, safety, and lifespan. The two most common material choices for battery enclosures are metal and plastic, each offering unique advantages and challenges.

In this article, we’ll explore the differences between metal and plastic enclosures, their suitability for lithium battery applications, and the factors you must consider when selecting. By the end of this guide, you’ll have a solid understanding of which material is best suited for your specific needs.

Part 1. What is a battery enclosure?

A battery enclosure is a protective housing designed to encase batteries, shielding them from environmental factors such as moisture, dust, and physical impact. It also ensures the battery’s safe operation by managing heat, preventing chemical leaks, and protecting users from electrical hazards.

Battery enclosures are critical components in applications ranging from electric vehicles to renewable energy systems, where the performance and durability of lithium batteries are paramount. The choice of material for the enclosure can significantly influence the battery system’s overall reliability and efficiency.

Artikel Terkait: Difference Between Battery Case and Battery Casing

Part 2. Why is material selection important for battery enclosures?

The material of a battery enclosure directly impacts several key aspects, including:

- Thermal management: Proper heat dissipation is crucial for lithium batteries to prevent overheating and thermal runaway.

- Durability: The enclosure must withstand physical shocks, vibrations, and external pressures.

- Weight: Lightweight materials are essential for portable devices or applications like electric vehicles.

- Corrosion resistance: Enclosures should resist wear from exposure to moisture, chemicals, or harsh weather conditions.

- Cost-effectiveness: Balancing performance and cost is vital for large-scale applications.

Choosing the right material ensures the battery’s safety, longevity, and optimal performance.

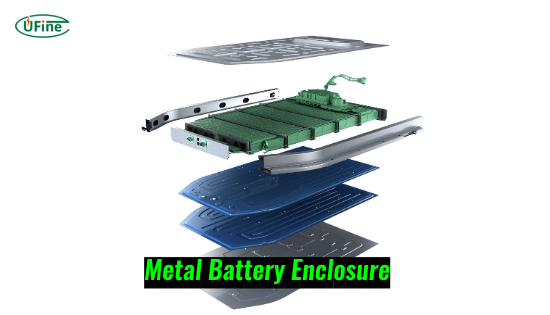

Part 3. Advantages of metal battery enclosures

- High strength and durability: Metal enclosures are known for their exceptional strength, making them ideal for high-durability applications. They can withstand impacts, harsh environments, and heavy loads without deforming or failing.

- Excellent thermal conductivity: Metals like aluminum and steel have high thermal conductivity, making them great for dissipating heat generated by lithium batteries. This feature helps maintain optimal operating temperatures and reduces the risk of overheating.

- Fire resistance: Metal enclosures are non-combustible and provide better protection against fire hazards than plastic. This is especially important for lithium batteries, posing safety risks if not properly managed.

- Shielding against electromagnetic interference (EMI): Metal enclosures offer natural shielding against electromagnetic interference, protecting the battery and surrounding electronics from signal disruptions.

Part 4. Disadvantages of metal battery enclosures

- Heavier weight: Metals are generally heavier than plastic, which can be a drawback for applications requiring lightweight components, such as drones or portable devices.

- Higher cost: Metal enclosures, particularly those made of aluminum or stainless steel, are more expensive than plastic alternatives.

- Corrosion risk: Although some metals are corrosion-resistant, others may require protective coatings or treatments to prevent rust and degradation over time.

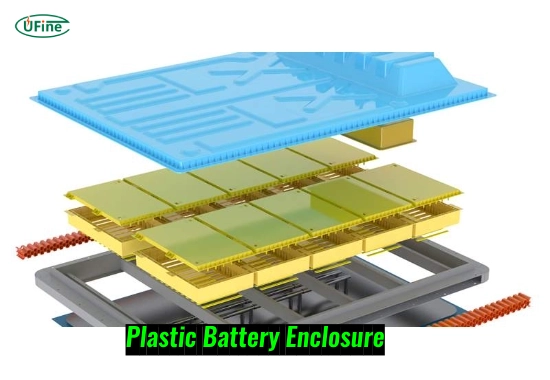

Part 5. Advantages of plastic battery enclosures

- Lightweight design: Plastic enclosures are significantly lighter than metal, making them ideal for applications where weight is critical, such as electric vehicles and handheld devices.

- Cost-effective: Plastic materials are often cheaper to manufacture and process, making plastic enclosures a more budget-friendly option for mass production.

- Corrosion resistance: Unlike metal, plastic is inherently corrosion-resistant, making it suitable for environments with high humidity or chemical exposure.

- Design flexibility: Plastics can be easily molded into complex shapes, allowing for greater design flexibility and integration of features like ventilation or cable management systems.

Part 6. Disadvantages of plastic battery enclosures

- Lower thermal conductivity: Plastic has poor heat dissipation properties compared to metal. This can lead to overheating issues in high-performance lithium battery systems.

- Reduced strength: Plastic enclosures are generally less durable than metal and may not withstand heavy impacts or extreme conditions as effectively.

- Flammability concerns: Some types of plastic are flammable, posing a safety risk in case of battery failure. However, flame-retardant plastic materials can mitigate this issue.

Part 7. Key factors to consider when choosing a battery enclosure material

When deciding between metal and plastic for your battery enclosure, consider the following factors:

- Application requirements: Assess your application’s specific needs, such as portability, thermal management, and durability.

- Operating environment: Determine the environmental conditions the enclosure will face, including temperature, humidity, and chemical exposure.

- Weight limitations: Optimize lightweight materials for applications like electric vehicles to improve efficiency.

- Safety standards: Ensure the material meets safety regulations and standards for lithium battery applications.

- Cost constraints: Balance the enclosure’s performance with your budget to make cost-effective decisions.

Part 8. Use cases for metal and plastic battery enclosures

Metal enclosures

- Electric vehicles: High durability and thermal management make metal ideal for EV battery systems.

- Industrial applications: Metal enclosures are preferred for rugged environments and heavy-duty use.

- Renewable energy systems: Metal protects batteries from harsh outdoor conditions.

Plastic enclosures

- Consumer electronics: Lightweight and cost-effective plastic is suited for portable devices.

- Medical devices: Plastic’s corrosion resistance and design flexibility are beneficial in healthcare settings.

- Lightweight robotics: Plastic enclosures reduce the overall weight of robotic systems.

Part 9. Common misconceptions about battery enclosure materials

- Plastic is always inferior to metal: While plastic may lack the strength of metal, advanced plastic materials can offer comparable performance for specific applications.

- Metal is always fireproof: Although metal does not burn, it can warp or melt under extreme heat, potentially compromising the enclosure’s integrity.

- Cost should be the only deciding factor: Focusing solely on cost can lead to suboptimal performance or safety issues. Always weigh cost against other critical factors, such as durability and thermal management.

Part 10. FAQs

-

What is the primary function of a battery enclosure?

A battery enclosure protects the battery from physical damage, environmental factors, and electrical hazards while ensuring safe and efficient operation. -

Which material, metal or plastic, is better for thermal management?

Metal is better for thermal management due to its high thermal conductivity, which helps dissipate heat more effectively. -

Are plastic battery enclosures safe for lithium batteries?

Plastic enclosures are safe when made from flame-retardant materials and designed to meet safety standards. -

Can metal enclosures corrode over time?

Yes, some metals can corrode if exposed to moisture or chemicals. Using corrosion-resistant metals or protective coatings can prevent this. -

Which material is more suitable for lightweight applications?

Plastic is more suitable for lightweight applications due to its low density and ease of molding into compact designs.

Related Tags:

More Articles

How to Choose the Best Floor Scrubber Battery for Commercial Cleaning?

Selecting the ideal floor scrubber battery ensures a long runtime, rapid charging, and minimal maintenance for efficient commercial cleaning operations.

Battery for Blower vs Battery for Leaf Vacuum: Which One Should You Choose?

Battery for blower vs leaf vacuum—learn the key differences in power, fit, and runtime to choose the right battery for your outdoor tool needs.

How to Choose the Right Battery for Blower?

Choosing the right blower battery? Consider voltage, capacity, chemistry & usage. This guide helps match the best battery for peak performance.

How to Choose the Best Insulated Battery Box for Lithium Batteries?

Choosing the Best Insulated Battery Box for Lithium Batteries? Discover key factors such as size, material, and safety for optimal protection and performance.

7 Critical Elements on a Lithium Battery Shipping Label

What must be on a lithium battery shipping label? Learn 7 key elements to ensure safety, legal compliance, and correct handling across all transport modes.