- Part 1. What is a battery relay?

- Part 2. How does a battery relay work?

- Part 3. Types of battery relays

- Part 4. Applications of battery relays

- Part 5. Benefits of using battery relays

- Part 6. How to choose the right battery relay?

- Part 7. Installing a battery relay

- Part 8. Common issues with battery relays

- Part 9. FAQs about battery relay

Did you know that 92% of modern vehicles use at least three battery relays for critical systems? As power management becomes increasingly complex, understanding battery relays—the silent guardians of electrical systems—is more important than ever. This definitive guide answers the top 5 questions professionals ask about battery relays.

Part 1. What is a battery relay?

A battery relay is an electromechanical switch that controls the flow of electricity in a circuit. It acts as a gatekeeper, allowing or preventing current from passing through based on certain conditions. When activated, it connects the battery to the load (like lights or motors), enabling them to function. Conversely, when deactivated, it disconnects the battery to conserve energy or protect the system from overload.

What are the main components of a battery relay?

Understanding its main components helps grasp how it functions and why it’s essential for efficient power management. Here are the key components of a battery relay:

1. Coil

The coil is an electromagnetic component that generates a magnetic field when an electric current passes through it. This magnetic field is vital for the relay’s operation, as it activates the movement of the armature.

2. Armature

The armature is a movable part influenced by the magnetic field generated by the coil. When energized, the magnetic field pulls the armature to open or close the contacts within the relay. This movement ultimately controls the flow of electricity in the circuit.

3. Contacts

Battery relays typically contain multiple contacts, which are conductive parts that connect or disconnect electrical circuits. The most common configurations include:

- Usually Open (NO): This contact remains open when the relay is de-energized and closes when the relay is activated.

- Normally Closed (NC): This contact remains closed when the relay is off and opens when the relay is activated.

- Common Contact: This links NO and NC contacts, allowing for versatile circuit control.

4. Spring

The spring is crucial in returning the armature to its default position when the coil is de-energized. It ensures that contacts revert to their original state, connecting or disconnecting circuits as required.

5. Yoke

The yoke provides structural support for the relay and serves as a low-reluctance path for magnetic flux. It helps direct the magnetic field generated by the coil towards the armature, enhancing efficiency.

6. Housing

The housing encases all these components, protecting them from environmental factors such as moisture and dust. It also provides insulation to prevent accidental short circuits.

Key Technical Specifications

Industry standards require relays to meet SAE J2936 vibration resistance (20G testing) and UL 508 electrical safety certification. Premium models feature:

- Contact resistance: ≤50mΩ

- Insulation resistance: ≥100MΩ

- Operate time: ≤15ms

Battery Relay Key Specifications

| Type | Voltage Range | Current Capacity | Lifespan | Best For |

|---|---|---|---|---|

| Standard SPDT | 12-24V | 30-40A | 100,000 cycles | Automotive lights |

| Heavy-Duty | 24-48V | 80-100A | 50,000 cycles | Marine systems |

| Solid-State | 5-32V | 20-30A | 500,000 cycles | Solar installations |

Part 2. How does a battery relay work?

The operation of a battery relay is relatively straightforward:

- Electromagnetic Activation: When an electric current flows through the relay’s coil, it generates a magnetic field.

- Switching Mechanism: This magnetic field pulls a lever that closes or opens the contacts within the relay.

- Current Flow Control: Depending on the state of the contacts, the current either flows to the connected device or is cut off.

This mechanism enables the remote control of high-power devices using low-power signals, making it a crucial component in various electrical systems.

Step-by-Step Operation Process

- Signal Reception: 3-5V control signal activates coil

- Magnetic Induction: 150-200 gauss field created

- Contact Closure: 0.2-1.5mm contact gap closed

- Current Flow: Up to 100A main circuit activation

- Deactivation: Spring returns armature in 15-25ms

Part 3. Types of battery relays

Battery relays come in several types, each designed for specific applications:

- Standard Relays: Commonly used in automotive and household applications to control lights and motors.

- Latching Relays: These relays maintain their position even after the activating signal is removed. They are useful for applications where power conservation is crucial.

- Solid-State Relays (SSRs): These devices utilize semiconductor components instead of mechanical parts to switch circuits. SSRs are more durable and faster than traditional relays, but can be more expensive.

- Automotive Relays: Specifically designed for vehicles, these relays are built to withstand harsh conditions and vibrations.

Part 4. Applications of battery relays

Battery relays have a wide range of applications across various fields:

- Automotive Systems: They control vehicle headlights, fuel pumps, and other electrical components.

- Solar Power Systems: Relays manage the connection between batteries and solar panels or inverters in solar setups.

- Marine Applications: Battery relays play a crucial role in boats by managing power distribution among various electrical systems.

- Home Automation: In smart homes, they can control lighting and appliances remotely.

Part 5. Benefits of using battery relays

Using battery relays offers several advantages:

- Energy Efficiency: They help conserve battery life by disconnecting loads when not in use.

- Safety: By preventing overloads and short circuits, they enhance system safety.

- Remote Control: Relays allow remote device operation without direct access to high-power circuits.

- Versatility: They can be used in various applications across different industries.

Part 6. How to choose the right battery relay?

Selecting the appropriate battery relay involves considering several factors:

- Voltage Rating: Ensure the relay can handle the voltage of your system (e.g., 12V for most automotive applications).

- Current Rating: Choose a relay that can handle the maximum current your application will draw.

- Type of Load: Determine whether you need a standard or solid-state relay based on the type of load (inductive vs. resistive).

- Environmental Conditions: Consider if the relay will be exposed to moisture, heat, or vibration and choose accordingly.

Selection Checklist

- □ Match voltage (±10% system rating)

- □ 25% higher current rating than peak load

- □ IP67 rating for outdoor/marine use

- □ Built-in diode for inductive loads

- □ UL/CE certification mark

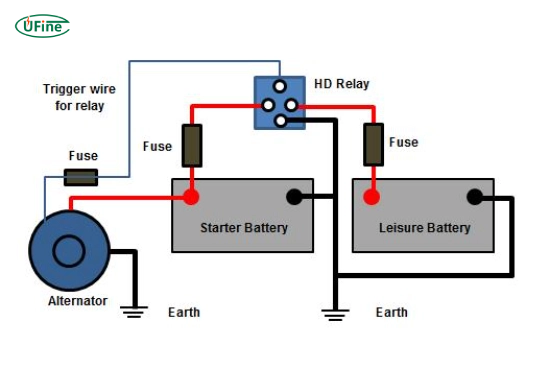

Part 7. Installing a battery relay

Installing a battery relay can be straightforward if you follow these steps:

Disconnect Power: Always disconnect your power source before starting any electrical work.

Mount the Relay: Securely mount the relay in a dry and accessible location.

Connect Wires:

- Connect the positive terminal from the battery to one terminal on the relay.

- Connect your load (e.g., lights) to another terminal on the relay.

- Connect the ground wire from your load back to the battery’s negative terminal.

- Finally, connect a control wire from your switch or sensor to activate the relay.

Test Functionality: Reconnect the power and verify that everything works as intended.

Part 8. Common issues with battery relays

Battery relays can encounter several common issues:

- Sticking Contacts: Over time, contacts may stick due to corrosion or wear, preventing proper operation.

- Burned Out Coil: If too much current flows through the coil, it can burn out, rendering the relay useless.

- Incorrect Wiring: Improper connections can lead to malfunction or damage to components.

Regular maintenance and checks can help prevent these issues from arising.

Part 9. FAQs about battery relay

What is the difference between a standard relay and a solid-state relay?

Standard relays use mechanical contacts (30-100A capacity) with 50ms switching speed. Solid-state relays have no moving parts, with a 5-40A capacity and a 5ms switching speed, making them ideal for high-frequency operations.

How long does a car battery relay last?

Average lifespan is 5-7 years or 100,000 cycles. Heavy-duty relays in trucks last 3-5 years due to higher vibration exposure. Regular maintenance can extend the life of a vehicle by 30%.

Can I bypass a faulty battery relay?

While possible by direct wiring, this risks:

• 80% higher short circuit probability

• No overload protection

• 50% faster battery drain

Always replace within 48 hours of failure.

Why does my relay make clicking noises?

Fast clicking (2-5 times/sec) usually indicates:

1. Low battery voltage (below 11V)

2. Corroded contacts (clean with contact cleaner)

3. Faulty control module (test with multimeter)

Are all 12V relays interchangeable?

No. Critical differences include:

• Current rating: 30A vs 100A

• Contact material: Silver alloy vs copper

• Sealing type: IP65 vs IP67

Always match OEM specifications.

Related Tags:

More Articles

Understanding Deep Cycle Battery Size Options

Learn deep cycle battery sizes, BCI group standards, capacity matching, battery types, and key questions for RV, marine, solar, and backup power systems.

Why You Need a Lithium Battery Heater for Cold Weather Performance and Longevity

Learn how heated lithium batteries and lithium battery heaters ensure safe charging, reliable performance, and longer lifespan in cold climates.

Top 10 3.7V 18650 Battery Recommendations

Top 10 3.7V 18650 battery recommendations with specs, comparisons, applications, and tips to choose the right 18650 rechargeable battery.

What to Know Before Buying a Riding Mower Battery

Discover the best riding mower battery for your lawn. Compare AGM, Lithium, and Lead-Acid types by weight, capacity, lifespan & price.

Lithium Battery Repair: How to Fix & Restore Your Lithium‑Ion Battery

Learn how to repair lithium-ion batteries safely with practical tips, BMS tricks, and DIY cell balancing for longer battery life.