Lithium batteries power many of our daily devices, from smartphones to electric vehicles. While we often focus on capacity and charge speed, one critical factor that is sometimes overlooked is the ends of the battery. These physical ends are the terminals and connectors that ensure electricity flows smoothly in and out of the battery. In this article, we will explore the various aspects of battery ends, why they matter, and how they influence overall lithium performance. We will discuss materials, design, temperature effects, and innovations. All explanations are written in a simple, conversational style so that even those new to the subject can easily follow along. Let’s dive into the essential world of battery ends.

Part 1. What are the physical ends of a battery?

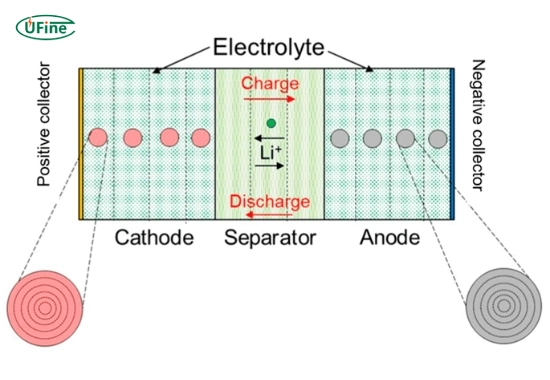

The physical ends of batteries refer to the terminal sections that connect the battery and the external circuitry. In simple terms, these are the points where current enters and leaves the battery. Every battery has two ends, typically a positive end and an opposing end.

The construction of these ends is more complex than it may seem. They are engineered with high precision to minimize resistance and ensure optimal electrical contact. Manufacturers choose these components carefully, knowing that even small imperfections can lead to poor performance or early failure. These connectors are not just metal strips but are designed to handle high currents, protect against environmental factors, and maintain a stable connection over time.

Moreover, battery ends are often treated with protective coatings. These coatings help prevent oxidation and corrosion, everyday issues that can deteriorate the battery’s efficiency. In summary, the physical ends of batteries are the unsung heroes in the design and performance of lithium batteries, ensuring that energy flows effectively and safely.

Part 2. How do physical battery ends influence lithium performance?

The ends of batteries play a crucial role in determining the overall performance of lithium batteries. Here’s how they make a difference:

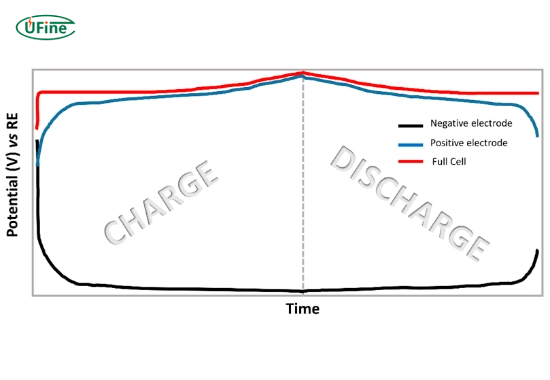

- Conductivity: The quality of the battery ends affects how well electricity flows. High-quality connectors reduce resistance. Lower resistance means that the battery can deliver power more efficiently.

- Thermal Management: Battery ends can influence the battery’s temperature profile. A well-designed end helps distribute heat evenly, preventing hot spots that can damage the internal components.

- Safety: Secure and robust battery ends reduce the risk of short circuits. They provide a reliable path for the electrical current, vital for safe operation.

- Energy Efficiency: Good contact between battery ends and external devices minimizes energy loss during transmission.

When the battery ends are not manufactured or maintained correctly, they can increase electrical resistance and inefficient energy flow. This inefficiency can affect the battery’s ability to charge quickly and hold a charge for a long time. It also plays a significant role in the battery’s lifespan. That is why paying attention to the ends of batteries is essential for anyone looking to maximize lithium battery performance.

Part 3. What are the key materials in battery ends?

The selection of materials for battery ends is a major factor in ensuring performance and durability. Common materials include:

- Copper: Often used for its excellent conductivity. Copper is a top choice for connectors due to its low resistance.

- Aluminum: Lightweight and corrosion-resistant. It is sometimes used in applications where weight is a critical factor.

- Special Alloys: Some high-performance batteries use alloys that combine copper, aluminum, and other metals. These materials can offer a balance between conductivity and durability.

- Protective Coatings: Many battery ends have a thin layer of coating. This coating protects the metal from oxidation and corrosion, which can occur due to exposure to moisture or chemicals.

Each of these materials is chosen for its specific properties. For example, copper is great for fast current transfer but can be heavy. Aluminum offers the benefit of being lightweight and less expensive, though it may not match copper’s conductivity. Using special alloys allows manufacturers to optimize the battery ends for both performance and cost. In every case, the goal is to produce a connector that stands up to high currents and harsh environments, thus preserving the integrity of the battery ends.

Artikel Terkait: Learn About the Battery Anode and Cathode

Part 4. How do battery design and construction affect performance?

The design and construction of battery ends are integral to the battery’s overall function. Let’s break down some of the key design elements:

- Shape and Size: The physical dimensions of battery ends must match the battery’s specific design. Even small deviations can lead to improper contact, which increases resistance and reduces efficiency.

- Mechanical Strength: Battery ends must withstand vibrations, shocks, and other physical stresses. A robust design ensures that connections do not loosen over time.

- Seal Integrity: A proper seal prevents moisture and contaminants from reaching the internal components, vital for maintaining the battery’s long-term reliability.

- Manufacturing Tolerances: Precision is key. High tolerances during manufacturing mean the parts fit together perfectly, ensuring a consistent and reliable connection.

A well-designed battery end not only improves the flow of electricity but also protects the battery from common issues like corrosion and mechanical damage. This directly influences the overall performance of lithium batteries. When every component—from the cell to the connector—is designed carefully, the result is a battery that can perform at its best under various conditions.

Part 5. What role does temperature play in battery ends?

Temperature is a key factor that can affect the ends of the battery. Batteries generate heat during operation, and the battery ends are not immune to these temperature changes. Here’s why temperature matters:

- Thermal Expansion: As temperatures rise, the metal in battery ends can expand. This expansion might lead to a looser connection, increasing resistance.

- Degradation: Prolonged exposure to high temperatures can cause materials to degrade. Corrosion can set in faster when the battery ends are exposed to heat, reducing their effectiveness.

- Efficiency Loss: When the battery gets too hot, it can lose some conductive properties. This loss can lead to lower performance and energy efficiency.

- Safety Concerns: Extreme temperatures may also increase the risk of short circuits or even thermal runaway in severe cases.

To counter these issues, many modern batteries include thermal management systems. These systems help maintain a stable temperature across the battery, including at its ends. Manufacturers can enhance performance and safety by keeping the ends of the battery within an optimal temperature range. This is especially important in high-demand applications like electric vehicles, where temperature fluctuations are typical.

Part 6. How do the physical ends of the battery affect battery longevity?

The durability of battery ends is a key factor in the overall lifespan of a battery. Over time, the quality of the connectors can degrade due to several reasons:

- Wear and Tear: Repeated charging and discharging cycles can cause small amounts of wear, which, over time, can lead to poor connections.

- Corrosion: Exposure to moisture, chemicals, and high temperatures can cause the metal in the battery ends to corrode. Corrosion can lead to increased resistance and even complete failure.

- Mechanical Fatigue: Constant vibrations and shocks, especially in mobile or vehicular applications, can weaken the battery ends. This mechanical fatigue reduces the reliability of the electrical connection.

Battery makers can extend the life of these critical components by using high-quality materials and ensuring precise manufacturing processes. Regular maintenance, such as cleaning and inspection, also plays a vital role in preventing premature failure. In essence, the ends of batteries are critical for performance and ensuring that the battery remains reliable over many charge cycles.

Part 7. What are common issues with battery ends in lithium batteries?

Lithium batteries, while highly efficient, are not immune to issues related to their physical ends. Some of the most common problems include:

- Corrosion: One of the leading causes of failure is corrosion. When moisture or chemicals come into contact with the battery ends, they can start to corrode. This corrosion increases electrical resistance and can eventually stop the flow of current.

- Loose Connections: Poor manufacturing or wear over time can result in loose connectors. A loose connection increases resistance and can lead to intermittent performance issues.

- Oxidation: Exposure to air can lead to oxidation of the metal surfaces in battery ends. Oxidized surfaces are less conductive and can hamper the overall performance.

- Physical Damage: Impacts, vibrations, or manufacturing defects can cause physical damage to the battery ends. Even a small dent or crack can significantly impact performance.

- Thermal Stress: Extreme temperatures can cause the metal components to expand and contract, weakening the battery ends over time.

Each of these issues can affect the performance of the battery ends and, by extension, the overall efficiency of the lithium battery. Manufacturers work hard to minimize these problems by using better materials, improving manufacturing techniques, and incorporating protective designs.

Part 8. How do we maintain and optimize battery end performance?

Keeping the ends of the battery in top condition is vital for maintaining overall performance. Here are some practical tips to ensure optimal performance:

- Regular Inspection: Check the battery ends periodically for signs of corrosion, oxidation, or physical damage. Early detection can prevent more severe issues.

- Cleaning: Use a soft cloth and a mild cleaning solution to wipe the battery ends gently. Avoid abrasive materials that might scratch or damage the surface.

- Secure Connections: Ensure that all connectors are tight and properly attached. Loose connections can lead to increased resistance and energy loss.

- Temperature Control: Store batteries in a cool, dry place. Avoid exposing them to extreme temperatures. Consider using additional cooling measures if the battery is used in a high-temperature environment.

- Proper Handling: Avoid dropping or mishandling batteries. Mechanical shocks can weaken the battery ends, leading to long-term issues.

- Quality Replacements: Always choose parts from reputable manufacturers when replacing or upgrading battery components. Using low-quality materials can compromise the performance of the ends of the battery.

Following these simple maintenance steps can help ensure your lithium batteries perform reliably and last longer. Regular maintenance is essential when batteries are used frequently or in harsh conditions.

Part 9. How do we test and monitor battery end efficiency?

Testing and monitoring the ends of the battery is essential to ensure it continues to perform at its best. There are several techniques and tools available to help with this:

- Resistance Measurements: One of the simplest tests is to measure the electrical resistance at the battery ends. Low resistance indicates a good connection, while higher values can signal potential issues.

- Thermal Imaging: Thermal cameras can help identify hot spots on the battery ends. Hot spots may indicate poor contact or areas where corrosion is starting.

- Visual Inspections: Regular visual checks can reveal physical damage, corrosion, or oxidation. Look for discoloration, pitting, or any signs of wear.

- Load Testing: By applying a known load to the battery and measuring voltage drop, you can infer the quality of the connections. Significant drops under load can indicate weak battery ends.

- Data Logging: Modern diagnostic tools can continuously log performance data from the battery ends. This data can track trends and predict when maintenance is needed.

These testing methods help ensure that the battery ends remain in top condition, contributing to lithium batteries’ overall reliability and performance. Regular monitoring can also help in the early detection of problems, allowing for timely repairs or replacements before a minor issue becomes a major failure.

Part 10. FAQs about ends of battery

What are the physical ends of a battery?

The physical ends of a battery are the terminal connectors that allow electrical current to flow in and out. They are designed to minimize resistance and ensure a secure connection. In summary, these ends are critical for proper battery function.

Why are the ends of the battery essential for lithium performance?

Battery ends play a key role in ensuring efficient power transfer. They reduce energy loss and help manage heat. A well-designed end improves conductivity and overall performance. Thus, they are essential for maintaining high lithium performance.

How can I improve the lifespan of my battery concerning battery ends?

You can extend battery life by regularly inspecting, cleaning, and securing all connections. Using quality components and maintaining an optimal temperature can also help. In short, proper care of the battery ends leads to a longer battery life.

What common issues can affect the ends of the battery?

Common issues include corrosion, oxidation, loose connections, physical damage, and thermal stress. These problems can increase resistance and reduce performance over time. Addressing these issues early is key to preventing battery failure.

Are there any innovations in battery ends technology that I should know about?

Yes, there are many exciting developments. Innovations such as advanced materials like graphene, nano-coatings, intelligent diagnostics, and modular designs are changing how battery ends are built and maintained. These advances promise improved durability and efficiency for lithium batteries.

Related Tags:

More Articles

The Ultimate Guide to 12V 18650 Battery Packs: Design, Benefits, and Applications

Looking for a reliable 12V power source? This guide covers 12V 18650 battery packs, their design, benefits, and applications.

9 Volt Battery Capacity Showdown: Lithium vs. Alkaline Batteries

Maximizing 9V battery capacity? This in-depth guide will help you compare lithium vs. alkaline batteries to choose the best option for your needs.

2200mAh Battery: Will It Meet Your Power Needs?

Is a 2200mAh battery right for you? Consider battery life, device usage, and cost. Discover if it meets your power needs. Read our guide now!

How to Pick the Best 12V 4Ah Battery?

Need a 12V 4Ah battery? We'll help you choose! Find compatible options for your electronics or mobility scooter. Read our simple tips and buy confidently!

Deep Cycle Camper Battery: Is It Right for You?

Deep cycle camper batteries boost power. They're reliable and last. Learn if this upgrade's worth it for your RV adventures. Read now!