Skinny batteries, also known as slim batteries or thin batteries, represent an emerging class of power storage solutions that are revolutionizing various industries, from wearables and smartphones to electric vehicles. These batteries are designed to be compact, lightweight, and energy-efficient while maintaining the necessary power output for modern technological applications. In this article, we will delve into the technical aspects of skinny batteries, how they differ from traditional power sources, and the materials and processes involved in their production.

Part 1. What are skinny batteries?

Skinny batteries are advanced, high-energy-density power storage systems prioritizing a slim form factor. Unlike conventional cylindrical or prismatic batteries, skinny batteries are often engineered to fit into spaces where traditional power sources cannot, such as wearables, smartphones, and increasingly compact consumer electronics. The defining characteristic of skinny batteries is their thinness and lightweight, which are achieved through sophisticated lithium-based chemistries and state-of-the-art manufacturing techniques.

Materials used in skinny batteries

Unlike traditional lead-acid or nickel-cadmium batteries, skinny batteries rely heavily on lithium-ion (Li-ion) or lithium-polymer (Li-Po) technology. These materials are chosen for their high energy density, lightweight nature, and ability to withstand high charge/discharge cycles without significant degradation.

- Lithium-ion (Li-ion) batteries are widely used due to their high efficiency and longer lifespan compared to older chemistries.

- Lithium-polymer (Li-Po) batteries, a variation of lithium-ion technology, allow for a more flexible form factor and are particularly useful in applications that demand a thin, flat design.

The core of skinny battery technology lies in using thin electrodes, such as cobalt oxide or nickel manganese cobalt (NMC), which provide high energy storage while remaining lightweight. The electrolytes are typically gel-based or solid-state, contributing to enhanced performance, faster charging times, and higher safety standards.

Part 2. How are skinny batteries different from traditional batteries?

Skinny batteries have been designed to address the limitations of traditional battery technologies. Let’s explore how skinny batteries differ from conventional options in several key areas:

1. Energy Density vs. Volume

While skinny and traditional batteries use similar chemistries, skinny batteries are designed to achieve a higher energy density per unit of volume. This is crucial for applications where compactness is vital. Traditional batteries provide more energy in larger forms. Still, they cannot deliver the same power level in the same compact space. This is achieved through advanced electrode materials and tight manufacturing tolerances that allow more active material to be packed into a thinner format.

2. Battery Chemistry and Manufacturing Process

Traditional batteries often rely on older materials like nickel-cadmium (NiCd) or nickel-metal hydride (NiMH), which are bulkier and less efficient than the lithium-based technologies used in skinny batteries. Lithium-ion and lithium-polymer technologies enable skinny batteries to achieve higher voltage levels and more excellent energy storage with significantly less weight and bulk.

In addition, solid-state batteries are an emerging technology used in some skinny battery designs. In these, a solid electrolyte replaces the traditional liquid or gel-based electrolyte. This reduces the battery’s size, improves safety, and increases energy density by allowing for thinner cell walls.

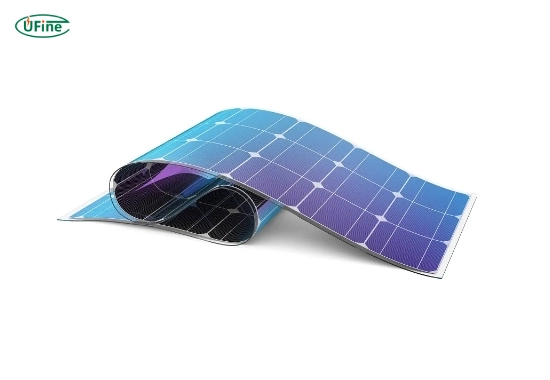

3. Flexibility and Thinness

One of the standout features of skinny batteries is their ability to be designed as flexible or thin-film batteries. This allows them to be incorporated into products that require non-traditional battery shapes, such as curved surfaces or wearable devices. Traditional batteries, by contrast, are generally rigid and need larger compartments, limiting their applications in such designs.

Part 3. Materials and technology behind skinny batteries

1. Lithium-based Electrodes and Electrolytes

The core of skinny battery technology lies in developing advanced lithium-based electrodes, which are much more energy-efficient than older chemistries. For example:

- Nickel Manganese Cobalt (NMC) electrodes are often used in high-performance skinny batteries due to their high capacity and thermal stability.

- Graphene-based electrodes are also gaining traction as they provide superior conductivity and lightweight properties while supporting faster charging speeds.

For the electrolytes, skinny batteries use polymer or solid-state electrolytes, which enable them to be slimmer without sacrificing safety or performance. These electrolytes are often non-flammable and offer more excellent thermal stability than liquid-based ones.

2. Manufacturing Processes: Precision and Innovation

The manufacturing of skinny batteries involves advanced processes such as precision layering and vacuum deposition. The electrodes and electrolytes are deposited in fragile layers to ensure the battery maintains a high energy density while being as compact as possible. Furthermore, nanotechnology enhances the electrode surface area, allowing for faster electron movement and excellent charge storage.

For example, roll-to-roll manufacturing allows manufacturers to produce thin-film batteries at a large scale, while vacuum evaporation techniques deposit thin electrode layers on flexible substrates. This cutting-edge manufacturing is one of the key reasons skinny batteries can maintain their lightweight and adaptable nature.

Part 4. Applications of skinny batteries

1. Smartphones and Tablets

One of the most significant applications of skinny batteries is smartphones and tablets, where manufacturers constantly push for slimmer and more robust designs. Skinny batteries allow for these devices to be lightweight, providing long battery life without sacrificing size or performance.

2. Wearables

Skinny batteries are an ideal power source for wearables like smartwatches and fitness trackers. These devices need compact, efficient batteries that fit seamlessly into the product’s form factor while offering long-lasting power. With the rise of flexible battery technology, wearables are expected to evolve with even thinner and more innovative designs.

3. Electric Vehicles (EVs)

In the electric vehicle industry, skinny batteries are making their way into smaller hybrid models and even some light electric vehicles (LEVs). The slim form factor of these batteries allows for optimized space usage, where the battery can be integrated into the vehicle’s structure without affecting aerodynamics or vehicle performance.

4. Medical Devices

From pacemakers to hearing aids, skinny batteries are indispensable in the medical field. These devices require reliable, long-lasting power in a tiny package to ensure patient comfort and device longevity. Advances in solid-state batteries offer even more promising prospects for the future of medical applications.

5. Consumer Electronics

Other consumer electronics, such as wireless earphones, smart glasses, and portable speakers, benefit from skinny batteries’ slim and efficient power. These devices demand high capacity in a small form factor, and skinny batteries meet these requirements, providing efficient power without bulk.

Part 5. Advantages of skinny batteries

There are several benefits to using skinny batteries in various applications:

- Compact design: The main advantage of skinny batteries is their slim, compact design. This allows for more flexibility in the product design they power, enabling manufacturers to create more portable, lightweight, and aesthetically pleasing devices.

- Improved performance: Despite their small size, skinny batteries often have a higher energy density than traditional batteries. This means they can store more power in a smaller volume, leading to longer-lasting performance in various applications.

- Space-saving: Since skinny batteries are smaller, manufacturers have more freedom in designing their products. This is particularly important in industries like wearables and smartphones, where space is at a premium.

- Faster charging times: Skinny batteries are often built with materials that enable faster charging. This can be a significant advantage for users who need quick top-ups throughout the day. Their design allows for efficient energy transfer and faster charging than traditional batteries.

- Environmentally friendly: Many modern skinny batteries are designed to be more environmentally friendly than traditional batteries. They often use recyclable materials or have a lower environmental impact, making them a more sustainable option in the long run.

Part 6. Challenges and limitations of skinny batteries

While skinny batteries are highly advanced and efficient, they do come with a few challenges:

- High Production Costs: The advanced materials and precision manufacturing required for skinny batteries make them more expensive to produce than traditional batteries. This higher production cost can drive up the price of end products, especially in competitive markets.

- Thermal Management Issues: Despite advancements in battery design, skinny batteries can face thermal issues during intense usage or rapid charging. Efficient thermal management systems must ensure these batteries remain within safe operating temperatures.

- Limited Capacity for Large-Scale Applications: Although skinny batteries offer high energy density for their size, their capacity is still limited compared to traditional, larger batteries. This can be a limitation for applications requiring extended power output, such as large electric vehicles or industrial applications.

Artikel Terkait: Lightweight Battery: Definitions, Types, Comparisons, and FAQs

Part 7. FAQs

-

What makes skinny batteries different from traditional batteries?

Skinny batteries differ in size, energy density, and the advanced materials used in their construction, such as lithium-polymer and solid-state technologies. -

Are skinny batteries suitable for electric vehicles?

Due to their compact form and high energy density, skinny batteries are used in smaller electric vehicles and hybrids. However, traditional batteries are more common for full-sized EVs. -

How are skinny batteries manufactured?

Skinny batteries are produced using advanced processes like precision layering, vacuum deposition, and roll-to-roll manufacturing, allowing for thin-film designs and high energy density. -

Can skinny batteries be flexible?

Yes, many skinny batteries are designed as flexible or thin-film batteries, making them ideal for applications in wearables and other curved devices. -

What are the main disadvantages of skinny batteries?

The main drawbacks of skinny batteries are their higher production costs, thermal management challenges, and limited energy capacity for specific applications.

Related Tags:

More Articles

6 Volt Batteries for RVs: Is It a Good Fit?

Need a reliable RV battery? Discover if a 6V battery's the right choice for your RV's power needs! Learn about RV battery types and make an informed decision now.

Flat Round Batteries vs. Coin Cell Batteries: What’s the Difference

Flat round and coin cell batteries are commonly used in electronics. This article explores their differences, features, and typical uses.

Understanding Round Batteries: Types, Sizes, and Their Applications

Round batteries power various devices like flashlights, watches, and remotes. This guide explores their types, sizes, features, and applications.

What’s a C Battery’s Voltage?

C batteries are usually 1.5 volts when new. The voltage goes down as they power your devices. Want to know more? Find out here!

Types of Flat Batteries: Choosing the Perfect Option for You

Flat batteries power everything from electronics to machinery. This guide covers types, uses, and tips for choosing the best one for your device.