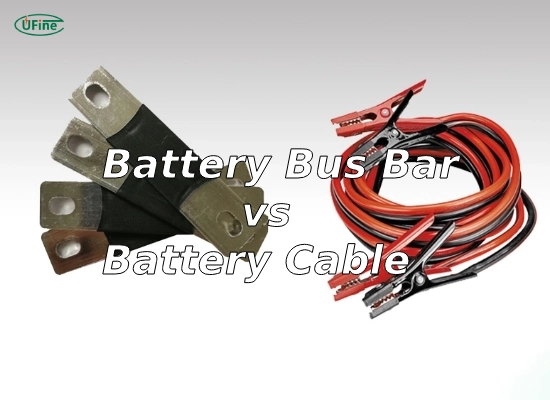

In the realm of electrical engineering, battery bus bars, and battery cables play pivotal roles in ensuring efficient power distribution. While they may seem similar at first glance, they serve different purposes and have distinct characteristics. This article aims to delve deep into the intricacies of battery bus bars and battery cables, shedding light on their functions, differences, and applications.

Part 1. What is a battery bus bar?

A battery bus bar is a robust metallic strip or bar that connects multiple battery cells within a battery pack or links various power distribution points in an electrical system. Typically made from conductive materials such as copper or aluminum, bus bars facilitate the transfer of large amounts of current with minimal resistance and heat generation.

Advantages of Using Battery Bus Bars

- Efficiency: Bus bars offer lower resistance than conventional wiring, leading to more efficient power transmission.

- Design Flexibility: They can be customized to fit specific applications, making them versatile in various setups.

- Heat Management: Due to their larger surface area, bus bars dissipate heat more effectively, reducing the risk of overheating.

- Space Saving: By consolidating connections into a single bar, bus bars help minimize clutter and save space within electrical panels.

Applications of Battery Bus Bars

- Electric Vehicles (EVs): Bus bars are integral in EV battery packs, ensuring efficient power distribution between cells and modules.

- Renewable Energy Systems: They are used in solar and wind energy installations to connect various components and manage power flow.

- Industrial Machinery: Bus bars facilitate power distribution in heavy machinery, ensuring consistent and reliable operation.

Part 2. What is a battery cable?

A battery cable is a flexible, insulated wire that transmits electrical power between a battery and other components. Manufacturers typically make these cables from copper or aluminum. They are insulated with materials like PVC (Polyvinyl Chloride) or rubber to prevent short circuits and ensure safety.

Advantages of Using Battery Cables

- Flexibility: Battery cables are highly flexible, making them easy to route through tight spaces and around obstacles.

- Durability: High-quality insulation protects against abrasion, chemicals, and environmental factors, ensuring long-term reliability.

- Versatility: They come in various gauges and lengths and are suitable for multiple applications, from automotive to marine and industrial.

Applications of Battery Cables

- Automotive: People commonly use battery cables to connect a vehicle’s battery to the starter and other electrical components.

- Marine: Battery cables ensure power distribution to various onboard systems in boats.

- Backup Power Systems: These are essential in UPS (Uninterruptible Power Supply) systems and other backup power solutions.

Part 3. Differences between battery bus bars and battery cables

Structural Differences

- Material and Construction: Bus bars are solid metal strips, whereas battery cables contain multiple strands of wire encased in insulation.

- Flexibility: Battery cables are flexible and can be bent or routed through complex pathways, unlike the rigid structure of bus bars.

Functional Differences

- Current Capacity: Bus bars can carry higher currents due to their larger cross-sectional area and lower resistance.

- Heat Dissipation: Bus bars have superior heat dissipation capabilities to battery cables, making them suitable for high-power applications.

Installation and Maintenance

- Ease of Installation: Battery cables are easier to install in confined spaces due to their flexibility, while bus bars require precise installation and secure mounting.

- Maintenance: Bus bars typically require less maintenance as they have fewer connection points than multiple battery cables.

Part 4. Choosing between battery bus bars and battery cables

Factors to Consider

- Current Requirements: Bus bars are generally preferred for high-current applications because they can handle larger currents efficiently.

- Space Constraints: Flexible battery cables may be more suitable in installations where space is limited.

- Environmental Conditions: Consider ecological factors such as temperature, moisture, and chemical exposure when choosing between bus bars and battery cables.

Cost Implications

- Initial Cost: Bus bars tend to be more expensive initially due to the cost of materials and manufacturing.

- Long-term Costs: Despite the higher initial cost, bus bars can offer savings in the long run due to reduced energy losses and maintenance needs.

Part 5. Installing and maintaining battery bus bars and cables

Installation Tips

- Proper Sizing: Ensure bus bars and battery cables are appropriately sized for their current to prevent overheating and energy loss.

- Secure Connections: Use appropriate connectors and ensure all connections are tight and safe to avoid voltage drops and potential faults.

- Routing and Layout: Plan the routing and layout of battery cables to minimize sharp bends and avoid areas with high temperatures or potential mechanical damage.

Maintenance Tips

- Regular Inspections: Conduct regular inspections to check for signs of wear, corrosion, or damage to bus bars and battery cables.

- Cleaning: Keep bus bars and battery cables clean and free from dust, dirt, and debris to ensure optimal performance.

- Monitoring Systems: Consider using monitoring systems to keep track of current flow, temperature, and other critical parameters.

Part 6. Battery bus bars and cables are common misconceptions

- Misconception 1: Bus Bars and Battery Cables are Interchangeable

While bus bars and battery cables may serve similar functions, they are not interchangeable. Each has specific applications where it excels; choosing the wrong one can lead to inefficiencies and potential hazards.

- Misconception 2: Higher Cost Always Means Better Performance

The cost of bus bars and battery cables can vary significantly based on materials and specifications. However, higher cost only sometimes equates to better performance. It is essential to consider the specific requirements of your application and choose the appropriate solution accordingly.

- Misconception 3: Maintenance is Not Necessary

Both bus bars and battery cables require regular maintenance to ensure optimal performance and longevity. Neglecting maintenance can increase resistance, overheating, and potential system failures.

Part 7. FAQs

-

Can battery bus bars be used in high-temperature environments?

Yes, battery bus bars can function in high-temperature environments if manufacturers use materials like copper or aluminum with proper insulation. Always check the manufacturer’s temperature ratings. -

How do I determine the right size for a battery bus bar?

Consider the current load, voltage, and environmental conditions to determine the correct size. Refer to manufacturer sizing charts and consult with an electrical engineer if needed. -

What are the safety precautions when handling battery bus bars?

Always turn off and disconnect power before handling. Wear protective gear like gloves and safety glasses. Use insulated tools and ensure all connections are tight and secure. -

Are battery cables and bus bars interchangeable?

No, they are not. Battery cables are flexible and used for movable connections. At the same time, bus bars are rigid and designed for stationary, high-current applications. Use each for its intended purpose.

Related Tags:

More Articles

How to Choose the Best Floor Scrubber Battery for Commercial Cleaning?

Selecting the ideal floor scrubber battery ensures a long runtime, rapid charging, and minimal maintenance for efficient commercial cleaning operations.

Battery for Blower vs Battery for Leaf Vacuum: Which One Should You Choose?

Battery for blower vs leaf vacuum—learn the key differences in power, fit, and runtime to choose the right battery for your outdoor tool needs.

How to Choose the Right Battery for Blower?

Choosing the right blower battery? Consider voltage, capacity, chemistry & usage. This guide helps match the best battery for peak performance.

How to Choose the Best Insulated Battery Box for Lithium Batteries?

Choosing the Best Insulated Battery Box for Lithium Batteries? Discover key factors such as size, material, and safety for optimal protection and performance.

7 Critical Elements on a Lithium Battery Shipping Label

What must be on a lithium battery shipping label? Learn 7 key elements to ensure safety, legal compliance, and correct handling across all transport modes.