When it comes to lithium battery manufacturing, achieving uniform coating is a game changer. A perfectly uniform coating doesn’t just look neat—it directly affects the performance, efficiency, and lifespan of the battery. In this article, we’ll explore what battery coating is, discuss the specific challenges of anode and cathode coatings, and highlight how companies like Ufine Battery are leading the way in solving these challenges.

Part 1. What is battery coating?

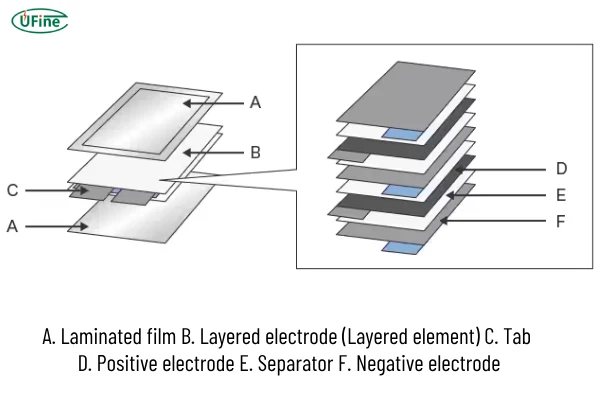

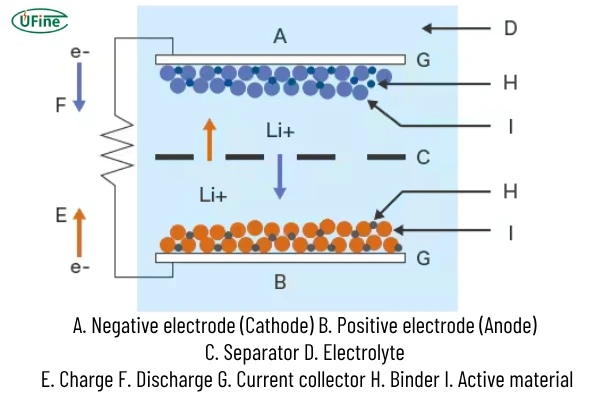

Battery coating refers to the process of applying active materials (like lithium compounds) onto the surface of electrode sheets in lithium-ion batteries. These electrode sheets, commonly made from materials like aluminum or copper foil, form the backbone of the battery.

The coating ensures the active materials are evenly distributed, allowing smooth electron and ion flow during the battery’s charge and discharge cycles. Proper coating is essential for:

- Energy efficiency: Maximizing capacity.

- Safety: Reducing the risk of overheating or short circuits.

- Longevity: Ensuring uniform wear across the battery’s lifespan.

Now, let’s dive into the specific challenges of coating for the positive (cathode) and negative (anode) electrodes.

Learn About the Cathode and Anode of the Battery

Part 2. Positive electrode (cathode) coating

The cathode is the “positive” side of the battery. It typically uses materials like lithium nickel cobalt manganese oxide (NCM) or lithium iron phosphate (LFP). These materials are crucial for the battery’s energy storage and output capabilities.

Challenges in Cathode Coating

-

Thickness Precision

Cathode materials need to be applied in a very specific thickness range. Too thick, and the battery’s energy density decreases. Too thin, and the active material may not provide enough capacity. -

Material Distribution

Cathode coatings often require precise mixing of active materials with conductive agents and binders. Any inconsistencies here can result in poor conductivity and uneven reactions. -

Temperature Sensitivity

Certain cathode materials are highly sensitive to the temperature during coating, which can cause cracks or delamination if not carefully controlled.

How to Improve Cathode Coating?

- High-precision equipment: Machines that can maintain consistent speed and pressure during application.

- Optimized slurry: Fine-tuned mixtures that ensure materials remain evenly suspended for smooth coating.

- Advanced monitoring systems: Real-time checks for evenness, preventing defects before they occur.

Ufine Battery has mastered these techniques, particularly with its advanced production lines for lithium iron phosphate (LFP) cathodes. Their focus on precision and quality ensures their batteries consistently deliver high performance and reliability.

Part 3. Negative electrode (anode) coating

The anode, the “negative” side of the battery, typically uses graphite or silicon-based materials. This part of the battery stores lithium ions during charging, playing a critical role in energy density and lifespan.

Challenges in Anode Coating

-

Uniform Particle Size

Graphite or silicon particles need to be finely distributed in the slurry. If not, uneven areas can form, leading to capacity loss or localized overheating. -

Binder Adhesion

Anodes require strong adhesion to the copper foil substrate. Weak adhesion can cause peeling or flaking, reducing the battery’s cycle life. -

Weight Consistency

For high-performance batteries, even tiny differences in coating weight can significantly affect energy density and overall performance.

How to Improve Anode Coating?

- Refined slurry preparation: Using nano-scale mixing to ensure even distribution of active materials and binders.

- Enhanced substrate adhesion: Pre-treating copper foil and using binders with optimal viscosity.

- Real-time weight checks: Automating weight monitoring to ensure every section of the anode meets exact standards.

At Ufine Battery, innovative techniques like nano-coating technology and automated weight monitoring systems ensure their anode coatings meet industry-leading standards. This meticulous attention to detail sets their batteries apart in terms of reliability and longevity.

Part 4. Why coating uniformity matters?

Coating is not just about looks—it plays a fundamental role in how a battery performs over time. Uniform coating ensures:

- Consistent performance: Balances electrochemical reactions.

- High energy density: Maximizes storage capacity.

- Longer lifespan: Reduces wear and tear on active materials.

Without proper coating, batteries risk performance degradation, safety issues, and shorter lifespans.

Part 5. How coating issues impact lithium battery performance?

1. Inconsistent Battery Capacity

Coating irregularities result in uneven distribution of active materials. This leads to capacity imbalances, where some parts of the battery wear out faster than others, reducing overall stability.

2. Lower Energy Density

Uneven or excessive coatings waste valuable space, decreasing the battery’s energy density. This affects applications where size and weight are critical, such as electric vehicles or portable devices.

3. Shorter Cycle Life

Uneven coatings cause stress during charge and discharge cycles, accelerating degradation. Batteries with poor coating may fail after fewer cycles.

Part 6. How to improve coating uniformity: effective solutions?

Improving coating uniformity requires high-quality materials, precise machinery, and optimized processes. Here are six practical steps to achieve better results:

1. Choose the Right Base Material

Start with flat, smooth foils for substrates. Uneven surfaces lead to coating inconsistencies and poor adhesion.

2. Optimize Adhesive Properties

Fine-tune viscosity to ensure the slurry spreads evenly and adheres well to the substrate.

3. Use Precision-Coated Rollers

Invest in high-precision rollers to ensure even pressure and distribution across the entire electrode surface.

4. Enhance Coating Machine Accuracy

Modern machines equipped with sensors and real-time adjustment features can drastically reduce coating flaws.

5. Optimize Key Parameters

Control variables like speed, temperature, and thickness to achieve a uniform coating every time.

6. Adopt Automation

Advanced automation minimizes human error, allowing for precise control and higher production consistency.

Ufine Battery sets a great example here. Their fully automated production lines and state-of-the-art coating equipment allow them to produce batteries with exceptional uniformity, meeting the most demanding standards.

Part 7. Final thoughts

Uniform coating is at the heart of a great lithium battery. It affects everything from capacity to safety and longevity. By focusing on high-quality materials, advanced machinery, and optimized processes, manufacturers can significantly improve battery performance.

Ufine Battery has established itself as a leader in this field. Their commitment to innovation and precision ensures every battery they produce meets the highest standards of performance and reliability. Whether it’s cathode or anode coating, they’ve perfected the art of achieving uniformity to deliver batteries that power everything from smartphones to electric vehicles.

In the end, every detail matters, and companies like Ufine Battery are setting the benchmark for excellence.

Related Tags:

More Articles

How to Choose the Best Floor Scrubber Battery for Commercial Cleaning?

Selecting the ideal floor scrubber battery ensures a long runtime, rapid charging, and minimal maintenance for efficient commercial cleaning operations.

Battery for Blower vs Battery for Leaf Vacuum: Which One Should You Choose?

Battery for blower vs leaf vacuum—learn the key differences in power, fit, and runtime to choose the right battery for your outdoor tool needs.

How to Choose the Right Battery for Blower?

Choosing the right blower battery? Consider voltage, capacity, chemistry & usage. This guide helps match the best battery for peak performance.

How to Choose the Best Insulated Battery Box for Lithium Batteries?

Choosing the Best Insulated Battery Box for Lithium Batteries? Discover key factors such as size, material, and safety for optimal protection and performance.

7 Critical Elements on a Lithium Battery Shipping Label

What must be on a lithium battery shipping label? Learn 7 key elements to ensure safety, legal compliance, and correct handling across all transport modes.